|

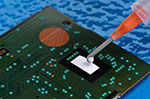

Master Bond manufactures a wide range of adhesives for bonding rubbers to rubbers, as well as rubbers to other substrates. Surface preparation plays a key role in ensuring that good bond strength is achieved. Typical techniques for proper rubber surface preparation include degreasing, abrasion and chemical treatment.

|

|

Epoxy System Adheres Well to Untreated Rubbers

|

Featuring excellent adhesion properties, EP21TDC-4 bonds well to metals, plastics and especially rubbers. In fact, it may adhere well to untreated rubber materials such as neoprene, nitrile, SBR and rubber compounds; which normally require time consuming surface preparation. The cured system has a peel strength greater than 30 pli and an elongation of over 200%.

For more information, request a technical data sheet on EP21TDC-4

|

|

Toughened System with Very Low Exotherm

|

Designed for bonding, coating, sealing and encapsulating, Master Bond EP21FL has a low viscosity and cures at room temperature. It is a toughened epoxy that is ideal for bonding dissimilar substrates with differing coefficients of expansion. EP21FL is effective for bonding surfaces subjected to rigorous thermal cycling and mechanical shock.

For more information, request a technical data sheet on EP21FL

|

|

Addition Cured Silicone with a Paste Consistency

|

MasterSil 153 is a two component silicone for high performance bonding and sealing that does not require exposure to air for complete cross-linking. It offers remarkable flexibility, high temperature resistance and has an exceptionally long working life with very low exotherm upon cure. It bonds well to silicone rubber and has superb electrical insulation properties.

For more information, request a technical data sheet on MasterSil 153

|

|

Thermally Conductive Epoxy Meets NASA Low Outgassing Specs

|

EP21TDC-2LO is a room temperature curing, flexibilized adhesive, sealant and encapsulant. This unique compound has superior shear and peel strength properties. It has an elongation of greater than 25% at 75°F and a Shore D hardness of 36. It offers remarkable resistance to chemicals, thermal shock and impact. The hardened system is an excellent electrical insulator.

For more information, request a technical data sheet on EP21TDC-2LO

|

|

Flexible Two Component Epoxy Withstands Thermal Cycling

|

Featuring thermal conductivity and electrical insulation, EP38FLAO is formulated for high performance bonding, sealing, coating, potting and encapsulation. It offers reliable chemical resistance to water, oils and many fuels. This flowable system has a low exotherm upon cure and a long working life. EP38FLAO bonds well to a wide variety of substrates and is serviceable over the temperature range of -100°F to +250°F.

For more information, request a technical data sheet on EP38FLAO

|

|

|

|

Copyright  2014 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc. 2014 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc.

|

|

View this email online

View this email online

April 2014

April 2014