|

MasterSil 713: Fast Curing, One Component, Non-Corrosive Silicone

MasterSil 713 is an easy to use silicone system with a remarkably low viscosity for bonding, sealing, coating, encapsulations and formed-in-place gaskets. Its low viscosity also enables this system to be used as a conformal coating. It can be cured in thicknesses up to ¼ inch deep with superb flexibility and elasticity. Additionally, this one part silicone has a service temperature range of -75°F to +400°F.

|

|

| For more information,

request a technical data sheet on MasterSil 713 |

|

|

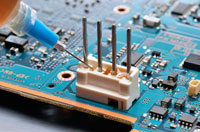

EP30AO: Thermally Conductive, Electrically Insulating Epoxy

Featuring an attractive blend of performance properties, Master Bond EP30AO possesses high thermal conductivity, first rate electrical insulation characteristics and superior dimensional stability. This two part epoxy cures at room temperature and has a low viscosity with good flow characteristics making it well suited as a thermally conductive, potting epoxy. The thermal expansion coefficient is desirably low.

|

|

| For more information, request a technical data sheet on EP30AO |

|

|

UV22: Optically Clear, Nanosilica Filled UV Curable Epoxy

UV22 will cure quickly and easily when exposed to a UV light source for bonding, sealing, coating and encapsulation applications. This nanosilica filled system retains full optical clarity and has enhanced abrasion resistance, dimensional stability and unsurpassed low shrinkage. Cationic systems, such as UV22, tend to have much higher temperature resistance than other UV systems. It has a glass transition temperature of 135°C.

|

|

| For more information, request a technical data sheet on UV22 |

|

|

Supreme 46HT-2ND2: Non-drip, Heat Resistant Epoxy Adhesive

Designed for high performance structural bonding, Supreme 46HT-2ND2 offers high shear and peel strengths and can withstand long-term exposure to temperatures from -100°F to +500°F. It produces durable, high strength, tough bonds which are remarkably resistant to thermal cycling as well as a wide variety of chemicals including water, many acids, bases, solvents, fuels and oils.

|

|

| For more information, request a technical data sheet on Supreme 46HT-2ND2 |

|

|

X17: Ideal for Polyolefin Bonding and Sealing

Master Bond X17 is a flowable, clear, one component adhesive for bonding polyolefins such as polypropylene and polyethylene without surface pretreatment. This synthetic elastomer-based adhesive compound exhibits an excellent balance of both shear and peel strength properties when bonding polyolefin substrates to each other and to related substrates including flexible PVC.

|

|

| For more information, request a technical data sheet on X17 |

|

|

EP42HT-2FG: High Temperature Resistant, Food Grade Epoxy System

Meeting the stringent requirements of FDA CFR 175.300 and the toxicological requirements of the NSF/ANSI 51(2009) Standard for Food Equipment Materials as defined in section 4.1, Master Bond EP42HT-2FG has wide applicability in the food industry. It has exceptional resistance to heat, boiling water, fats, oils and many other chemicals, as well as steam and radiation. This two part system is well suited for bonding metals, plastics, rubbers and other substrates common to the manufacture of food service equipment.

|

|

| For more information, request a technical data sheet on EP42HT-2FG |

|

|