|

|

| White Paper: Polymeric Systems Bring Clarity to Optical Applications |

Many optical assembly applications require optical clarity across a certain wavelength, while others need an opaque coating. Optical grade epoxies, silicones and UV curable coatings provide the versatility to adhere well to a wide variety of substrates and the critical performance properties to meet specific requirements. This white paper examines optical transmission, refractive indices, temperature and humidity testing, as well as the roles of these measurements in choosing an effective and reliable optical polymer system.

|

|

|

| Epoxy for Industrial Manufacturing Applications |

This unique two part epoxy is especially recommended where a thin layer of epoxy needs to cure very rapidly without adding external heat. Films as thin as 0.025 inches can become tack free in under 30 minutes. EP30-4 features a low viscosity with exceptional adhesion to similar and dissimilar substrates. It is optically clear with superior non-yellowing properties. It is also noteworthy for offering low linear shrinkage upon curing.

For more information, request a technical data sheet on EP30-4 |

|

|

| Polymer System Features Outstanding Non-Yellowing Properties |

EP21LSCL-1 is a two component, low viscosity epoxy system featuring superb optical clarity and non-yellowing properties. This versatile system can be used for high performance coating, bonding, sealing, encapsulation and casting. EP21LSCL-1 has an exceptionally long open time and features very low exotherm, making it ideal for potting in deep cross section thicknesses. It is serviceable from -60°F to +250°F and retains outstanding electrical insulation characteristics after long-term aging.

For more information, request a technical data sheet on EP21LSCL-1 |

|

|

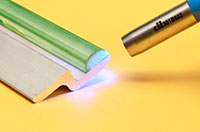

| Flowable, No-Mix LED Curable Polymer System |

Featuring breakthrough LED curing technology, LED401LV will cure completely tack-free when exposed to a light source emitting 405 nm wavelength in sections of 1/8 inch thick and beyond. Once cured, it has impressive physical properties, including outstanding dimensional stability, very good electrical insulation, optical clarity and commendable chemical resistance. Since LED light sources do not generate as much heat as UV ones, LED401LV can be used to bond heat sensitive substrates.

For more information, request a technical data sheet on LED401LV |

|

|

| Low Stress Silicone System Requires No Mixing |

MasterSil 920-LO is an ideal material for the encapsulation of sensitive electronic and optical components, especially when low stress is a critical requirement. It is a neutral curing, non-corrosive, RTV silicone that has very good flow properties. It also features outstanding electrical insulation values, which enhance its use as a conformal coating system. This product can also withstand rigorous thermal cycling, resists up to +500°F [+260°C] and is NASA low outgassing compliant.

For more information, request a technical data sheet on MasterSil 920-LO |

|

|

|

Copyright  2017 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc. 2017 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc.

|

|

View this email online

View this email online

September 2017

September 2017