|

|

| White Paper: Use of Epoxies as Protective Coatings against Corrosion for Metals |

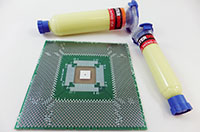

The unique requirements of microelectromechanical systems (MEMS) call for specialized materials. Versatile epoxy adhesives are often capable of providing the necessary properties to ensure support and protection from thermal and mechanical shock, vibration, high acceleration, particles, and other physical damage. Improved capabilities have enhanced the advantages of using these systems for die attach, underfill and encapsulation to meet demanding MEMS packaging requirements. This white paper will focus on how these materials are used and their benefits for MEMs applications.

|

|

|

| Epoxy Is Well Suited for Die Attach Applications |

Single component Supreme 3HTND-2DA offers convenient processing and dispensing with no tailing or bleed out and only requires simple refrigeration for storage. It cures rapidly in 5-10 minutes at 150°C. This toughened system has high die shear strength, superior electrical insulation properties, excellent thermal conductivity, low ionics and performs well in 85/85 testing. It also passes NASA low outgassing tests.

For more information, request a technical data sheet on Supreme 3HTND-2DA |

|

|

| Epoxy Has Ultra Low Coefficient of Thermal Expansion |

Featuring an exceedingly low coefficient of thermal expansion of 9-12 x 10-6 in/in/°C, EP42HT-2LTE is a two component epoxy for bonding, sealing, coating and select casting applications. It has outstanding dimensional stability and will bond well to a wide variety of substrates, including metals, composites, ceramics, glass and many plastics. It is also noteworthy for its low linear (less than 0.01%) and volumetric (less than 0.1%) shrinkage. EP42HT-2LTE has a forgiving, non-critical mix ratio of 100 to 50 by volume and after mixing the consistency is that of a paste with some flow.

For more information, request a technical data sheet on EP42HT-2LTE |

|

|

| Room Temperature Curing, Silver Filled Epoxy |

Silver filled, electrically conductive, room temperature curing EP21TDCS has a convenient one to one mix ratio, by weight or volume. This two part adhesive readily develops high peel and shear strength properties and is resistant to thermal cycling and many chemicals. It is serviceable over the wide temperature range of 4K to +275°F enabling it to be used in cryogenic applications. EP21TDCS also exhibits a high thermal conductivity and a volume resistivity of less than 10-3 ohm-cm.

For more information, request a technical data sheet on EP21TDCS |

|

|

| Quick Curing Epoxy Offers Superior Chemical Resistance |

One part epoxy system, EP3RRLV is formulated for high performance potting, encapsulation and underfill applications. This low viscosity adhesive withstands heat and thermal cycling. It also is resistant to mechanical vibration and shock. EP3RRLV is widely used in microelectronic assembly and packaging applications where excellent electrical insulation and fast cure times are essential. This unique formation can be cast up to 1 inch deep and has superior heat dissipation properties.

For more information, request a technical data sheet on EP3RRLV |

|

|

| Durable UV Curable System for Glob Top Applications |

Delivering superior resistance to chemicals, UV15X-2GT is a one part UV curable glob top with easy processing characteristics. This thixotropic paste features excellent electrical insulation properties, cures rapidly and is commonly employed for encapsulating selected components and chips on circuit boards. As a toughened formulation, it has outstanding mechanical and thermal shock resistance as well as the ability to easily withstand thermal cycling over its service temperature range of -80°F to +250°F. UV15-2GT is available for use in bottles, can and syringe applicators.

For more information, request a technical data sheet on UV15X-2GT |

|

|

|

Copyright  2016 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc. 2016 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc.

|

|

View this email online

View this email online

February 2016

February 2016