|

|

Behind the Bonds: 40 Years of Adhesive Manufacturing - Part 2 |

Master Bond is keeping its 40th anniversary party going. In this video, find out how Master Bond expanded over the years to produce new product lines and formulations that serve a variety of industries across the world.

|

| Toughened epoxy is NASA low outgassing approved |

Serviceable up to 400°F, Supreme 11AOHT-LO features exceptional thermal conductivity and electrical insulation properties for high performance bonding and sealing applications. This two part system delivers impressive toughness which enables it to withstand rigorous thermal cycling and makes it particularly well suited for bonding dissimilar substrates. Formulated to cure at ambient temperatures, Supreme 11AOHT-LO has a convenient one to one mix ratio and meets NASA low outgassing specifications.

For more information, request a technical data sheet on Supreme 11AOHT-LO

|

| Epoxy features exceptional high strength properties |

Combining high shear and peel strength, Supreme 10HT is a versatile system with convenient handling. This outstanding epoxy offers tensile lap shear strengths in excess of 3,600 psi and T-peel strengths up to 30 pli. It readily withstands severe thermal cycling along with mechanical shock and vibration. This one part system will not thicken over time, eliminates complicated mixing and cures in just 60-75 minutes at 250°F. It can withstand severe environments ranging from cryogenic temperatures down to 4K up to +400°F.

For more information, request a technical data sheet on Supreme 10HT

|

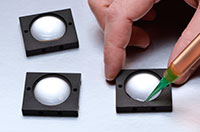

| Flowable, no mix LED curable polymer system |

Featuring breakthrough LED curing technology, LED401LV will cure completely tack-free when exposed to a light source emitting 405 nm wavelength in sections of 1/8 inch thick and beyond. Once cured, it has impressive physical properties, including outstanding dimensional stability, very good electrical insulation, optical clarity and commendable chemical resistance. Since LED light sources do not generate as much heat as UV ones, LED401LV can be used to bond heat sensitive substrates.

For more information, request a technical data sheet on LED401LV

|

| High temperature resistant silicone system cures rapidly |

One component MasterSil 711 is a room temperature, non-corosive curing silicone compound for bonding, sealing, coating and formed-in-place gaskets. It offers superior shock and impact resistance making it ideal for delicate electronic components. Flexible bonds are formed when exposed to atmospheric moisture. MasterSil 711 requires no mixing or heat, and sets within 2-3 minutes.

For more information, request a technical data sheet on MasterSil 711

|

| High viscosity epoxy adhesive features superior shock resistance |

High performance EP21TDCF-3 produces bonds and seals with remarkably high tensile strength and peel strength exceeding 7,500 psi and 35 pli respectively. This two part, thixotropic paste adhesive offers a fast fixture speed, superior resistance to thermal cycling and is serviceable over the wide temperature range of -100°F to more than 250°F. It can also withstand exposure to many aggressive chemicals. EP21TDCF-3 features a convenient, non-critical one to one mix ratio by weight or volume.

For more information, request a technical data sheet on EP21TDCF-3

|

|

|

|

Copyright  2016 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc. 2016 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc.

|

|

View this email online

View this email online

April 2016

April 2016