|

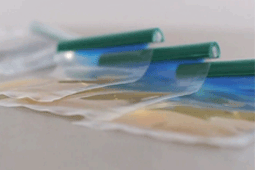

How to Use a Flexible Divider Pouch

|

|

Through simple step by step instructions, Master Bond demonstrates the proper way to use a flexible divider pouch. This pre-measured packaging system offers a number of benefits including improved efficiency and waste elimination. Watch now

|

|

|

|

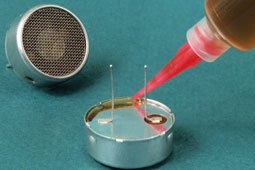

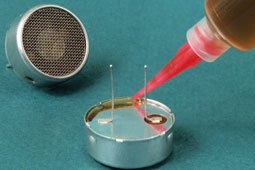

EP21LV

|

|

EP21LV is a low viscosity epoxy for high performance bonding, sealing, coating, encapsulation and casting. This two part system produces high strength, durable bonds which hold up well to thermal cycling and resists many chemicals. EP21LV meets FDA Chapter 1, Section 175.105 requirements for indirect food contact.

Request a data sheet on EP21LV

|

|

|

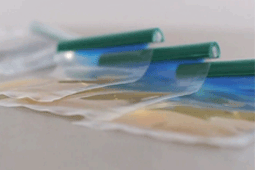

EP30HT-LO

|

|

EP30HT-LO cures rigid with exceptional dimensional stability and physical strength properties. The shrinkage upon curing is very low—less than 0.1%. Most notably, it also combines heat resistance with excellent optical clarity. This is a special version of EP30HT that has passed testing for NASA low outgassing based on ASTM E595.

Request a data sheet on EP30HT-LO

|

|

|

|

EP21TDC-4

|

|

Featuring excellent adhesion properties, EP21TDC-4 bonds well to metals, plastics and especially rubbers. In fact, it may adhere well to untreated rubber materials such as neoprene, nitrile, SBR and occasionally EPDM rubber compounds; materials that normally require time consuming surface preparation. The cured system has a peel strength greater than 30 pli and an elongation of over 200%.

Request a data sheet on EP21TDC-4

|

|

|

EP42HT-2

|

|

With remarkable heat resistance to 450°F, EP42HT-2 is a room temperature curable, two component epoxy adhesive, sealant, coating and casting material. It is resistant to a wide variety of acids, bases, solvents, fuels, oils and salts. The system has superior optical transmission properties, particularly in thinner sections, as well as a high index of refraction for an epoxy.

Request a data sheet on EP42HT-2

|

|

|

|

Can You Re-use a Flexible Divider Pouch?

|

As a matter of fact, you can. Here's how:

- Leave the barrier in place

- Cut the corners for the resin and the catalyst

- Measure and mix small amounts of each according to the mix ratio

- Clip or seal the bubble pack for future use

|

|

|

|

154 Hobart Street, Hackensack, New Jersey, USA

|

|

|

|

|

|

|

|

|