|

|

| New White Paper: Spotlight on Silicones |

Silicone adhesive systems have several important performance characteristics that distinguish them from other adhesive families. Learn more about their unique combination of flexibility, high temperature resistance, and more specialized engineering properties.

|

|

|

|

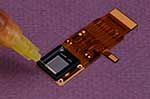

Flowable, NASA Low Outgassing Silicone System |

With a tensile strength of 325-425 psi, MasterSil 921-LO offers good adhesion to a wide variety of substrates including metals, composites, ceramics, glass as well as many rubbers and plastics. This one part silicone has a flowable, moderate viscosity that enables it to be well suited for smaller potting and encapsulation applications. Its lower durometer of 25-35 Shore A hardness facilitates its use with sensitive components, particularly electronic and optical ones.

For more information, request a technical data sheet on MasterSil 921-LO |

|

|

| Flexible, Flame Retardant Compound |

Featuring a rapid non-corrosive cure, MasterSil 708FR is often selected for bonding and sealing applications that require flame retardancy. It is UL listed with a flame classification for 94V-1 for thicknesses of 0.75 mm and 94V-0 for a 3 mm thickness. This formulation is exceptionally soft with superb elasticity, flexibility and outstanding electrical insulation properties.

For more information, request a technical data sheet on MasterSil 708FR |

|

|

| Optically Clear, Water Resistant Silicone Compound |

Featuring outstanding electrical insulation properties and a low viscosity, MasterSil 151 is ideal for high performance potting, casting and encapsulation. This flexibilized system also provides superior resistance to vibration and shock as well as high strength and elongation. Serviceable over the wide temperature range of -65°F to +400°F, MasterSil 151 cures at room temperature or faster at elevated temperatures.

For more information, request a technical data sheet on MasterSil 151 |

|

|

| High Performance Silicone Is Serviceable up to +300°C |

Thermally stable, MasterSil 801 is a high performance, one part silicone for bonding, sealing, coating and formed-in-place gaskets. It is extremely soft with superb flexibility and elasticity that provides top notch electrical insulation properties. This specialty system features a non-corrosive cure, making it highly desirable for many applications, especially those pertaining to electronics and aerospace.

For more information, request a technical data sheet on MasterSil 801 |

|

|

| One Part Adhesive Offers High Transparency |

Optically clear MasterSil 415 silicone adhesive/sealant is widely employed for its reliable and high quality performance for bonding, and sealing metal and most plastics where transparency is a critical factor. It has a paste consistency and will not sag, slump or run off surfaces. It cures at ambient temperatures to a flexible rubbery solid when exposed to atmospheric moisture.

For more information, request a technical data sheet on MasterSil 415 |

|

|

| Single Component Heat Dissipative Silicone Compound |

Master Bond MasterSil 705TC is a one component, thermally conductive, electrically isolating silicone for bo nding, sealing and coating applications. It features outstanding thermal conductivity and is well suited for applications that require flexibility and high temperature resistance. It cures readily at ambient temperatures when exposed to atmospheric moisture and is a non-corrosive type silicone. MasterSil 705TC is also ideal for a variety of applications where a degree of reworkability is desired.

For more information, request a technical data sheet on MasterSil 705TC |

|

|

|

Copyright  2015 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc. 2015 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc.

|

|

View this email online

View this email online

May 2015

May 2015