|

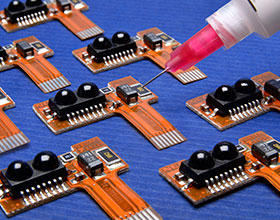

Master Bond EP3UF is a one component epoxy that contains thermally conductive fillers with very small particle sizes imparting a low thermal resistance of 5-7 x 10-6 K•m2/W. This low viscosity system has good flow properties and can be applied in bond lines as thin as 10-15 microns. It offers a thermal conductivity of 9-10 BTU•in/ft2•hr•°F [1.30-1.44 W/(m•K)] and a volume resistivity exceeding 1014 ohm-cm. EP3UF also passes NASA low outgassing tests and can be used for bonding and underfills in microelectronics packaging/assembly applications.

As a single component system, EP3UF is easy to handle with an “unlimited” working life at room temperature and fast cures at temperatures as low as 250°F. This high performance system delivers a tensile strength of 5,000-7,000 psi and a compressive strength of 18,000-20,000 psi. It bonds well to a variety of substrates such as metals, composites, ceramics, and many plastics. This dimensionally stable compound has low shrinkage upon curing.

EP3UF withstands many chemicals, including water, cleaning solvents, oils and fuels. This light yellow colored epoxy is serviceable over the temperature range of -60°F to +250°F [-51°C to +121°C]. It is available for use in 10 cc syringes, 30 cc syringes, ½ pint and pint containers and has a 6 month shelf life at room temperature in its original, unopened containers.

For more information on EP3UF, request a technical data sheet.

|

View this email online

View this email online

July 2016

July 2016