EP42HT-2FG: Food Grade Epoxy Is Heat Resistant |

|

|

Meeting the most stringent requirements of FDA CFR 175.300, EP42HT-2FG also complies with the NSF/ANSI 51(2009) Standard for Food Equipment Materials as defined in section 4.1. It has wide applicability in the food industry as an adhesive and sealant. It is well suited for bonding metals, plastics, rubbers and other substrates common to the manufacture of food service equipment including bins, hoppers and containment vessels. EP42HT-2FG also will resist boiling water, radiation, chemicals, steam and frozen storage conditions. This product is serviceable from -60°F to +450°F [-51°C to +232°C].

For more information, request a data sheet on EP42HT-2FG

|

|

|

EP3UF: Ideal for Underfill Applications |

|

|

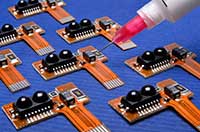

EP3UF is a one component epoxy that contains thermally conductive fillers with very small particle sizes and features a low thermal resistance of 5-7 x 10-6 K•m2/W. This low viscosity system has good flow properties and can be applied in bond lines as thin as 10-15 microns. It offers a thermal conductivity of 9-10 BTU•in/ft2•hr•°F [1.30-1.44 W/(m•K)] and a volume resistivity exceeding 1014 ohm-cm. EP3UF also passes NASA low outgassing tests.

For more information, request a data sheet on EP3UF

|

|

|

EP30-2: Optically Clear Epoxy Meets NASA Low Outgassing Specifications |

|

|

EP30-2 is a two component epoxy adhesive, sealant and laminating compound. It cures at room temperatures and has a low mixed viscosity. Bonds are rigid. EP30-2 can resist temperatures up to 300°F and is optically clear. NASA low outgassing approved, this compound can withstand exposure to thermal cycling and chemicals. It is also cryogenically serviceable.

For more information, request a data sheet on EP30-2

|

|

|

EP41SMed: Low Viscosity, Medical Grade Epoxy Compound |

|

|

USP Class VI approved, EP41SMed is well suited for a variety of uses in disposable/reusable medical devices as an adhesive, sealant and coating. This epoxy system is very fast curing at room temperature and produces high strength rigid bonds, which are remarkably resistant to chemical sterilants such as ethylene oxide, bleach, glutaraldehyde and hydrogen peroxide based systems. It has a service temperature range of -60°F to + 250°F and exceptionally low linear shrinkage upon cure. EP41SMed is easy to apply, is 100% reactive and possesses excellent electrical insulation characteristics.

For more information, request a data sheet on EP41SMed

|

|

|

MasterSil 155: Tough, Flexible Electrical Conductive Silicone |

|

|

MasterSil 155 is a graphite filled, two component silicone with a smooth paste consistency which assures complete fill-in around contours in a variety of bonding, sealing and gasketing applications. It is widely used for electronic components, electrical devices and various electro-optical systems as well as for special electronic circuitry. This product cures to a black rubber and offers superior protection against vibration, impact and shock. It is well suited for dissipating static electricity and for EMI/RFI shielding.

For more information, request a data sheet on MasterSil 155

|

|

|

Supreme 11AOHT: Thermally Conductive, Electrically Insulating Epoxy |

|

|

This room temperature curing epoxy combines a variety of high performance properties for bonding and sealing applications. Most importantly, Supreme 11AOHT delivers superior thermal conductivity of 9-10 BTU•in/ft2•hr•°F [1.30-1.44 W(m•K)] and a volume resistivity of >1014 ohm-cm. It also produces bonds with exceptionally high shear and peel strengths of 3,200-3,400 psi and 15-20 pli at 75°F, respectively. This toughened two part system is able to withstand rigorous thermal cycling over the wide service temperature range of -100°F to +400°F [-73°C to +204°C].

For more information, request a technical data sheet on Supreme 11AOHT

|

|

newsletters@masterbond.com newsletters@masterbond.com

+1 201 343 8983 +1 201 343 8983

Copyright  2017 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc. 2017 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc.

|

|

|

|

View this email online

View this email online

April 2017

April 2017