|

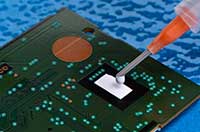

MasterSil 801: Serviceable Up to +300°C |

|

|

MasterSil 801 is a one component silicone paste for high performance bonding, sealing, coating and formed-in-place gasketing applications. This non-corrosive system can be used in sections up to a 1/4 inch thick and forms a soft flexible, rubbery solid that resists thermal and mechanical shock. MasterSil 801 is widely used within the aerospace and electronic industries and it will not depolymerize when exposed to ultra high temperatures/pressures.

For more information, request a technical data sheet on MasterSil 801

|

|

EP42HT-2FG: Food Grade, Heat Resistant Epoxy |

|

|

Meeting the most stringent requirements of FDA CFR 175.300, EP42HT-2FG also complies with the NSF/ANSI 51(2009) Standard for Food Equipment Materials as defined in section 4.1. It has wide applicability in the food industry as an adhesive and sealant. It is well suited for bonding metals, plastics, rubbers and other substrates common to the manufacture of food service equipment including bins, hoppers and containment vessels. EP42HT-2FG also will resist boiling water, radiation, chemicals, steam and frozen storage conditions.

For more information, request a data sheet on EP42HT-2FG

|

|

|

EP46HT-2Med: USP Class VI Epoxy with a Tg over 220°C |

|

|

Master Bond EP46HT-2Med is a two component biocompatible epoxy for high performance structural bonding and casting. It is suitable for applications where resistance to temperatures from -100°F to +550°F is required and high mechanical strength/chemical resistance is needed. EP46HT-2Med is also resistant to radiation, chemical sterilants and repeated autoclaving. This compound has good flow properties, a long working life at room temperature and low exotherm upon cure.

For more information, request a data sheet on EP46HT-2Med

|

|

|

EP3SP5FL: One Component “Snap Cure” Epoxy Adhesive |

|

|

Featuring an extraordinary combination of properties, EP3SP5FL is a one component epoxy offering snap cures of 1-2 minutes at 300°F. It has high strength properties, superior electrically insulation and is readily reworkable. With a flowable, moderate viscosity, EP3SP5FL adheres well to a variety of substrates including metals, composites, glass, ceramics, many rubbers and plastics. Additionally, it can withstand exposure to thermal cycling.

For more information, request a data sheet on EP3SP5FL

|

|

|

UV10TK40: Offers Exceptionally High Glass Transition Temperature |

|

|

UV10TK40 features temperature resistance up to 450°F and a glass transition temperature of 140°C. This one part, high viscosity UV system also offers excellent dimensional stability. Optically clear UV10TK40 can cure in sections up to 0.090-0.100 inches when exposed to a UV light source. It is effectively used for high volume production applications where fast fixture times and rapid curing are critical.

For more information, request a data sheet on UV10TK40

|

|

|

EP38FLAO: Flexible Epoxy Withstands Thermal Cycling |

|

|

Delivering superior thermal conductivity and electrical insulation properties, EP38FLAO is formulated for high performance bonding, sealing, coating, potting and encapsulation. It offers reliable chemical resistance to water, oils and many fuels. This two component, flowable system has a long working life, low exotherm upon cure and can be employed it large volume encapsulation applications. EP38FLAO bonds well to a wide variety of substrates and is serviceable over the temperature range of -100°F to +250°F.

For more information, request a data sheet on EP38FLAO

|

|

newsletters@masterbond.com newsletters@masterbond.com

+1 201 343 8983 +1 201 343 8983

Copyright  2016 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc. 2016 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc.

|

|

|

|

View this email online

View this email online

June 2016

June 2016