|

EP30Med: Low Viscosity Epoxy Meets USP Class VI |

|

|

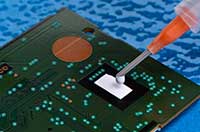

Ideal for encapsulation, bonding and sealing applications, Master Bond EP30Med offers a low viscosity, excellent electrical insulation properties and exceptionally low shrinkage upon cure. It is a two component, room temperature curing epoxy adhesive designed for high performance medical applications. It features high bond strength, superior durability and outstanding chemical resistance. This biocompatible system is widely used in the manufacturing of medical devices. It also meets FDA requirements for indirect food contact as per FDA CFR 175.105.

For more information, request a data sheet on EP30Med

|

|

|

UV22: Nanosilica Filled Epoxy System |

|

|

Featuring superb optical clarity, UV22 will cure quickly and easily when exposed to a UV light source. Cationic systems, such as UV22, tend to have much higher temperature resistance than other UV type systems. Its glass transition temperature (Tg) with a straight UV cure is 100°C, and when post cured for 30 minutes at 125-150°C, the Tg is 135°C. This dimensionally stable epoxy also has excellent abrasion resistance.

For more information, request a data sheet on UV22

|

|

|

EP38FLAO: Flexible Epoxy Withstands Thermal Cycling |

|

|

Delivering superior thermal conductivity and electrical insulation properties, EP38FLAO is formulated for high performance bonding, sealing, coating, potting and encapsulation. It offers reliable chemical resistance to water, oils and many fuels. This two component, flowable system has low exotherm upon cure and a long working life. EP38FLAO bonds well to a wide variety of substrates and is serviceable over the temperature range of -100°F to +250°F.

For more information, request a data sheet on EP38FLAO

|

|

EP79FL: Silver Coated Nickel Conductive Epoxy |

|

|

Master Bond EP79FL is a silver coated, nickel filled polymer system that forms high strength bonds even at extreme cryogenic temperatures. It is electrically conductive and has minimal sagging while maintaining thermal cycling resistance. As a silver coated nickel filled system is much more cost effective than conventional silver filled epoxies. EP79FL is a strong and flexible system with exceptional chemical resistance properties.

For more information, request a data sheet on EP79FL

|

|

|

Supreme 10ANHT-LO: One Part Epoxy Meets NASA Low Outgassing Specifications |

|

|

Offering high strength properties, Supreme 10ANHT-LO is a single component heat curing system that is serviceable over the wide temperature range of 4K to +400°F. This toughened formulation is thermally conductive and electrically insulative. It is also dimensionally stable and withstands rigorous thermal cycling.

For more information, request a data sheet on Supreme 10ANHT-LO

|

|

|

EP112LS: Ideal for Impregnation Applications |

|

|

EP112LS is optically clear, features reliable non-yellowing properties and has a refractive index of 1.55. This electrically insulative system is resistant to chemicals including water, oils, fuels, acids and bases. Featuring a mixed viscosity of 50-200 cps, EP112LS is serviceable over the temperature range of -60°F to +450°F.

For more information, request a data sheet on EP112LS

|

|

newsletters@masterbond.com newsletters@masterbond.com

+1 201 343 8983 +1 201 343 8983

Copyright  2014 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc. 2014 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc.

|

|

|

|

View this email online

View this email online

July 2014

July 2014