|

Shining a light on incredible toughness, Master Bond EP38CL is a two component epoxy that withstands rigorous thermal cycling and mechanical shock. This durable system also boasts superior optical clarity and a high physical strength profile.

|

|

|

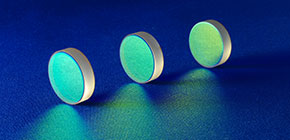

Optically Clear Adhesives, Sealants and Coatings

|

|

|

EP30-2 is an optically clear epoxy that meets NASA low outgassing specifications and resists temperatures up to 300°F. Its durable and tough bonds maintain outstanding resistance to thermal cycling and chemicals. Learn more

|

|

NASA low outgassing approved, Master Bond epoxy adhesive EP29LPSP is specially formulated for cryogenic applications at temperatures as low as 4K. EP29LPSP has a low mixed viscosity, long working life and high bond strength. Learn more

|

|

Single component UV15-7 delivers superior physical strength properties, low shrinkage upon curing and good non-yellowing stability. It exhibits outstanding durability and good electrical insulation properties. Learn more

|

|

Master Bond EP37-3FLF is a low viscosity, two component epoxy system specifically designed for bonding, coating and potting. It exhibits superb light transmission properties, high flexibility and resistance to vibration, impact and shock. Additionally, EP37-3FLF is cryogenically serviceable. Learn more

|

|

Two component, low viscosity EP21LSCL-1 offers superb non-yellowing properties. It has an exceptionally long open time and features very low exotherm making it ideal for casting up to 2-3 inches thick. Learn more

|

|

One part MasterSil 415 silicone adhesive/sealant is widely employed for its reliable and high quality performance for bonding, and sealing metal and most plastics where transparency is a critical factor. It has a paste consistency and will not sag, slump or run off surfaces. Learn more

|

|

|

|

|

Inside Our Lab

Every bonding application has its own unique set of performance challenges. Among the most severe is exposure to vibration and thermal shock. The development of liquid elastomers has aided in the creation of toughened epoxies with substantially extended service temperature ranges. Formulations have now been developed for use in severe vibration, impact and thermal shock environments. Added flexibility permits bonded parts to absorb stresses created by rapid temperature changes, vibration and impact.

Learn more about the benefits of toughened adhesives in our Technical Tip: Epoxy Adhesives That Resist Vibration & Thermal Shock

|

|

|

|

|

154 Hobart Street, Hackensack, New Jersey, USA

|

|

|

|

|

|

Copyright © 2014 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc.

|

|

|