|

The non-halogenated EP90FR series of products sets a new standard of flame retardancy as it meets FAR 14 CFR 25.853(a) specifications for both vertical and horizontal burn tests. This strict industry certification is often required for specialty aerospace applications such as interior panels, door frame lining, floor/door assemblies, etc.

|

|

MasterSil 707FR

|

MasterSil 707FR passes UL testing with a flame classification for 94V-1 for thicknesses of 0.75 mm and 1.5 mm, and 94V-0 for a 3 mm thickness. It adheres well to a wide variety of substrates including glass, metals and many plastics. This system is room temperature curing, but the rapidity of the cure depends on the thickness of the layer and the humidity.

For more information, request a data sheet on MasterSil 707FR |

|

EP21FRNS-2 |

Featuring a non-halogenated filler, EP21FRNS-2 is a two component, room temperature curing epoxy offering low smoke generation for potting, encapsulating and casting applications. As per the UL 94V-0 specification, this system is serviceable over the wide temperature range of -60°F to 200°F. It is remarkably resistant to thermal cycling and many chemicals. EP21FRNS-2 is exceptionally durable/tough and features a convenient one to one mix ratio by weight.

For more information, request a data sheet on EP21FRNS-2 |

| EP29LPSP |

EP29LPSP is a two component, low viscosity epoxy system for bonding, sealing and coating. This epoxy not only functions at temperatures as low as 4K, but also withstands cryogenic shocks. Additionally, it meets NASA low outgassing requirements. EP29LPSP provides superior physical strength, high chemical resistance, excellent electrical insulation and outstanding optical clarity.

For more information, request a data sheet on EP29LPSP |

| Supreme 10ANHT-LO |

Offering high strength properties, Supreme 10ANHT-LO is a single component heat curing system that is serviceable over the wide temperature range of 4K to +400°F. This toughened formulation is thermally conductive and electrically insulative. It is also dimensionally stable and withstands rigorous thermal cycling. This epoxy passes NASA low outgassing ASTM E595 testing.

For more information, request a data sheet on Supreme 10ANHT-LO |

| UV10TKLO-2 |

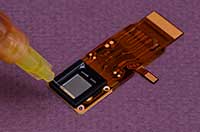

UV10TKLO-2 is a special one component UV curable epoxy modified system for high performance bonding, sealing and encapsulation. This system can be cured up to 1/16 of an inch and can be easily “layered” to higher levels. Most significantly, its low outgassing properties enable this UV product to be used in a wide array of optical, electro-optical and vacuum applications that until now have been “off limits” for UV curable epoxies.

For more information, request a data sheet on UV10TKLO-2 |

newsletters@masterbond.com newsletters@masterbond.com

+1 201 343 8983 +1 201 343 8983

Copyright  2015 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc. 2015 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc.

|

|

|

|

View this email online

View this email online

March 2015

March 2015