|

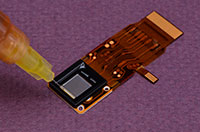

MasterSil 711: Very Fast Curing Silicone System

With an extraordinarily fast non-corrosive cure, Master Bond MasterSil 711 is ideal for bonding, sealing, coating and formed-in-place gasket applications, especially those involving electronics. It is extremely soft with superb flexibility and elasticity and outstanding electrical insulation properties.

|

|

| For more information,

request a technical data sheet on MasterSil 711 |

|

|

MasterSil 156: Thermally Conductive & Meets UL 94V-0 Specification

Featuring superb electrical insulation properties Master Bond MasterSil 156 is a two component, low viscosity silicone system for high performance potting, encapsulation and sealing. It combines high temperature resistance, flexibility, thermal conductivity along with meeting UL 94V-0 for flame retardancy.

|

|

| For more information, request a technical data sheet on MasterSil 156 |

|

|

MasterSil 705TC: Single Component Heat Dissipative Silicone Compound

MasterSil 705TC is a thermally conductive, electrically isolating silicone for bonding, sealing and coating applications. It is well suited for applications that require flexibility and high temperature resistance. It cures readily at ambient temperatures when exposed to atmospheric moisture and is a non-corrosive type silicone. It is also ideal for a variety of applications where a degree of reworkability is desired.

|

|

| For more information, request a technical data sheet on MasterSil 705TC |

|

|

MasterSil 153Med: Biocompatible, Addition Cured Silicone

Formulated for medical device applications, MasterSil 153Med passes USP Class VI and ISO 10993-5 testing. This two component, addition cured system does not require exposure to air for complete cross-linking. With a convenient one to one mix ratio by weight, it will not outgas while curing. Other features include remarkable flexibility and high temperature resistance while maintaining very low exotherm over an exceptionally long working life.

|

|

| For more information, request a technical data sheet on MasterSil 153Med |

|

|

MasterSil 708FR: Flame Retardant Compound

Featuring a rapid non-corrosive cure, MasterSil 708FR is often selected for bonding and sealing applications that require flame retardancy. It is UL listed with a flame classification for 94V.1 for thicknesses of 0.75 mm and 94V.0 for a 3 mm thickness. This formulation is exceptionally soft with superb elasticity, flexibility, and outstanding electrical insulation properties.

|

|

| For more information, request a technical data sheet on MasterSil 708FR |

|

|

MasterSil 415: Offers High Transparency

MasterSil 415 silicone adhesive/sealant is widely employed for its reliable and high quality performance for bonding, and sealing metal and most plastics where transparency is a critical factor. It has a paste consistency and will not sag, slump or run off surfaces. It cures at ambient temperatures to a flexible rubbery solid when exposed to atmospheric moisture.

|

|

| For more information, request a technical data sheet on MasterSil 415 |

|

|