|

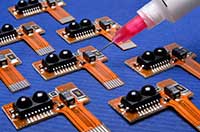

With 2017 on the horizon, it is the perfect time to reflect on what our most outstanding accomplishments were this past year. Here are some of the breakthrough epoxies, silicones and UV curable products that were developed in 2016 at a glance.

|

|

Supreme 18TC: Thermally Conductive Epoxy Meets NASA Low Outgassing Specifications |

Supreme 18TC is a one component conductive epoxy adhesive featuring unmatched heat transfer capabilities. This thermal conductive and electrically insulative system is capable of being applied in thin bond lines (10-15 microns) and meets NASA low outgassing specifications. It has a smooth paste consistency and cures quickly with the addition of heat. Some other positives include low shrinkage upon curing, a low CTE and a high degree of dimensional stability. It bonds well to a wide variety of substrates including metals, composites, ceramics and most plastics.

For more information, request a technical data sheet on Supreme 18TC

|

| EP3UF: Ideal for Underfill Applications |

EP3UF is a one component epoxy that contains thermally conductive fillers with very small particle sizes imparting a low thermal resistance of 5-7 x 10-6 K•m2/W. This low viscosity system has good flow properties and can be applied in bond lines as thin as 10-15 microns. It offers a thermal conductivity of 9-10 BTU•in/ft2•hr•°F [1.30-1.44 W/(m•K)] and a volume resistivity exceeding 1014 ohm-cm. EP3UF also passes NASA low outgassing tests.

For more information, request a technical data sheet on EP3UF

|

| MasterSil 910Med: One Part, Medical Grade Silicone System Cures Rapidly |

Passing both USP Class VI testing and ISO cytotoxicity specifications, MasterSil 910Med is formulated for bonding, sealing, coating of medical devices. As an acetoxy type system, it bonds exceptionally well to a wide variety of substrates including metals, composites, ceramics, glass as well as many rubbers and plastics. Tack free time can range from 10-20 minutes at 75°F. This compound withstands liquid sterilants, gamma radiation and EtO very well. Its service temperature range is -75°F to +400°F.

For more information, request a technical data sheet on MasterSil 910Med

|

|

EP113: Optically Clear, Nanosilica Filled Epoxy

|

Formulated for potting, coating and sealing applications, EP113 is a two component, nanosilica filled epoxy. The nano particles enhance dimensional stability and its already exceptionally low shrinkage upon curing. This low viscosity system bonds well to a wide variety of substrates including metals, composites, glass, ceramics and plastics. As a toughened compound, it has good resistance to thermal cycling and shock over the wide temperature range of -100°F to +450°F [-73°C to +232°C]. Additionally, this compound is a top tier electrical insulator.

For more information, request a technical data sheet on EP113

|

|

EP29LPAO: Thermally Conductive & Electrically Insulative System

|

EP29LPAO is a two component epoxy well suited for potting and encapsulating, even in large volumes. This product has a low exotherm, a long working life of 7-9 hours at room temperature for a 100 gram mass, excellent flow properties and ambient/low temperature curing characteristics. Additionally, EP29LPAO offers an outstanding strength profile, with a tensile modulus of 450,000-500,000 psi and a compressive strength of 24,000-26,000 psi at 75°F. Adhesion to a wide range of substrates such as metals, glass, ceramics and many plastics is excellent.

For more information, request a technical data sheet on EP29LPAO

|

|

|

|

Copyright  2016 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc. 2016 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc.

|

|

View this email online

View this email online

December 2016

December 2016