EP21ND-LP: Two Part Epoxy Paste with Long Working Life |

|

|

Featuring excellent physical strength properties, EP21ND-LP is a room temperature curing epoxy for bonding, sealing and coating applications. This system has a non-critical one to one mix ratio by weight or volume and a 2-4 hour working life after mixing. Its durable bonds hold up well to thermal cycling and resist many chemicals including water, oils, fuels, acids, bases and salts. It bonds well to a variety of substrates including metals, composites, glass, ceramics and many types of rubbers and plastics. Once cured, this product is an excellent electrical insulator. Properties of EP21ND-LP can be adjusted by altering the mix ratio.

For more information, request a data sheet on EP21ND-LP

|

|

|

EP79FL: Silver Coated Nickel Conductive Epoxy |

|

|

EP79FL is a silver coated nickel filled polymer system that forms high strength bonds that are resistant to extreme cryogenic temperatures. It is electrically conductive and has a volume resistivity of <0.005 ohm-cm. As a silver coated nickel filled system, it is much more cost effective than conventional silver filled epoxies. EP79FL is a flexible system with exceptional chemical resistance properties. The adhesive spreads evenly and smoothly. It has a convenient one to one mix ratio by weight and cures at ambient temperatures.

For more information, request a data sheet on EP79FL

|

|

|

MasterSil 711: Ultra Fast Curing, High Temperature Resistant Silicone |

|

|

One component MasterSil 711 is a room temperature, non-corrosive curing silicone compound for bonding, sealing, coating and formed-in-place gaskets. It offers superior shock/impact resistance and is ideally suited for sealing delicate electronic components. Flexible bonds are formed when exposed to atmospheric moisture. MasterSil 711 requires no mixing or heat, and sets within 2-3 minutes.

For more information, request a data sheet on MasterSil 711

|

|

|

LED403Med: LED Curable System Meets USP Class VI Specifications |

|

|

One part LED403Med cures in thin sections in 15-30 seconds upon exposure to a 405 nm wavelength LED light. Featuring excellent optical clarity and superior light transmission properties, it fully cures tack-free without any oxygen inhibition. This dimensionally stable system resists various sterilization methods including gamma radiation, and passes the plastics test for USP Class VI biocompatibility and ISO 10993-5 cytotoxicity requirements.

For more information, request a data sheet on LED403Med

|

|

|

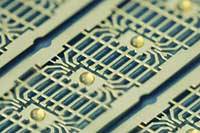

EP17HTDA-1: Heat Resistant Epoxy for Die Attach Applications |

|

|

Formulated for die attach applications, Master Bond EP17HTDA-1 is a one component epoxy that can also be used for conventional bonding and sealing. This system features an excellent die shear strength of 24-27 kg-f and can be used in a typical die size ranging from 4-400 mm2. EP17HTDA-1 has superb temperature resistance with a service temperature range of -80°F to +600°F [-62°C to +316°C] and a Tg of 195-205°C. It features thermal conductivity of 9-10 BTU•in/ft2•hr•°F [1.30-1.44 W/(m•K)] and has reliable electrical insulation properties. EP17HTDA-1 can also be used in vacuum situations as it passes NASA low outgassing testing.

For more information, request a data sheet on EP17HTDA-1

|

|

|

EP30TC: Low Thermal Resistance, Room Temperature Curing Epoxy |

|

|

Formulated for thermal management applications, EP30TC is a two component epoxy that contains robust thermally conductive fillers with very fine particle sizes. It has thermal conductivity of 18-20 BTU•in/ft2•hr•°F [2.60-2.88 W/(m•K)] and can applied in sections as thin as 5-15 microns, resulting in a low thermal resistance of 7-10 x 10-6 K•m2/W. This NASA low outgassing certified system can be used for bonding, coating, sealing and encapsulating for the aerospace, electronic, optical and OEM industries.

For more information, request a technical data sheet on EP30TC

|

|

newsletters@masterbond.com newsletters@masterbond.com

+1 201 343 8983 +1 201 343 8983

Copyright  2017 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc. 2017 by Master Bond Inc. All Rights Reserved. This content may not be reproduced in any way without the prior written permission of Master Bond Inc.

|

|

|

|

View this email online

View this email online

September 2017

September 2017