Expanded Product List

Master Bond Product Search

178 products match

|

EP79FL Highly flexible, silver coated/nickel filled epoxy system. T-pee >20 pli. Low volume resistivity. High bond strength to similar and dissimilar substrates. Resists exposure to thermal cycling. Serviceable from 4k to +275°F. One to one mix ratio by weight. Ambient temperature curing. 100% reactive. Withstands moisture, chemical exposure. Available in premixed and frozen syringes. |

|

EP93AOFR Two component high strength flame retardant epoxy system that meets stringent horizontal burn test portion of the FAR standard 14 CFR 25.853(a). Non-halogenated system serviceable from -80°F to +300°F. Forgiving one to one mix ratio by weight. Good electrical insulation. |

|

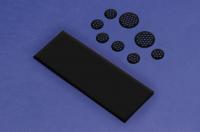

FL901AO High performance, thermally conductive, electrically insulative, resin based epoxy adhesive film system. Offers superior mechanical strength, convenient handling, good storage stability and fast cures at moderate temperatures. Uniform bond line thickness. Special preforms can also be prepared in multiple shapes and sizes. Serviceable from -100°F to +400°F. |

|

FL901S High performance, silver filled epoxy adhesive film system with outstanding electrical and thermal conductivity. Superior mechanical strength, convenient handling, good storage stability and fast cures at moderate temperatures. Specialty preforms are available. Serviceable from -100°F to +500°F. |

|

FLM36 B-staged film adhesive/sealant. Outstanding thermal cycling capabilities and structural properties. Offers superior toughness and flexibility. Excellent strength retention at elevated temperatures. Thermally conductive/electrically insulative. Provides uniform bond line thickness. Serviceable from -100°F to +500°F. Preforms are available. |

|

FLM36-LO NASA low outgassing approved B-stage epoxy adhesive. Tough and flexible. Elongation is greater than 50%. Thermally conductive/electrically insulative. Withstands rigorous thermal cycling. Can be die cut into custom shapes. Squeeze out is minimal. Ideal for applications requiring precise bond lines. Resists up to +500°F. |

|

MasterSil 151AO Thermally conductive silicone casting, potting and sealing system. Thermal conductivity of 0.35-.0.54 W/(m•K). Electrically isolating. Low viscosity system bonds well to a wide variety of substrates. Remarkable flexibility. Temperature resistant from -65°F to +400°F. White color. |

|

MasterSil 151S Addition curing, two part silicone for use as an adhesive, sealant, coating or form-in-place gasketing material. Despite its silicone chemistry, it passes NASA low outgassing specifications. It is ideal for applications where low stress is required. |

|

MasterSil 151TC Optically clear, addition curing potting, encapsulation, sealing compound. Low shrinkage upon cure. Resists up to +400°F [+204°C]. Shore A hardness 50-60. Highly resistant to water. Long pot life. Primarily in thermal management applications. |

|

MasterSil 155 Two part, graphite filled silicone adhesive. Convenient one to one mix ratio by weight. Volume resistivity 20-40 ohm-cm. Elongatio >300%. Serviceable from -85°F to +400°F. |