Some high performance epoxies can be formulated as B-stage systems. A B-stage epoxy is a system wherein the reaction between the resin and the curing agent/hardener is not complete. Due to this, the system is in a partially cured stage. When this system is then reheated at elevated temperatures, the cross-linking is complete and the system fully cures.

There are several advantages to using a B-stage system. The need for measuring and mixing is eliminated since this is a one part system. In many cases, B stage epoxies help to increase the performance of the product and decrease the overall manufacturing/production cost. Also, B-stage systems can be more convenient to use than a two part epoxy system in many applications. They can be deposited on a substrate and do not have to be cured immediately.

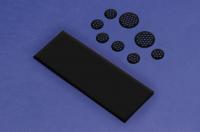

While B-staged epoxies can be packaged in standard cans, the uniqueness of these systems allows them to be manufactured in two distinct forms:

Characterized by high bond strength, these solid adhesives adhere well to both similar and dissimilar substrates and provide excellent resistance to chemicals and moisture. B-staged epoxy systems offer storage stability at ambient temperatures, and longer storage life with refrigeration.

Master Bond Popular Products

|

FLM36-LO NASA low outgassing approved B-stage epoxy adhesive. Tough and flexible. Elongation is greater than 50%. Thermally conductive/electrically insulative. Withstands rigorous thermal cycling. Can be die cut into custom shapes. Squeeze out is minimal. Ideal for applications requiring precise bond lines. Resists up to +500°F. |

|

EP36FR Flame retardant B-stage toughened epoxy. One part system. Ideal for potting and encapsulation. Capable of withstanding rigorous thermal shocks. Serviceable from -100°F to +500°F. Available in 30 gram cookies. |

|

EP36AO Thermally conductive, electrically insulative B-stage toughened epoxy. One part system. Ideal for potting and encapsulation. Capable of withstanding rigorous thermal shocks. Serviceable from -100°F to +500°F. Available in 30 gram cookies. Meets NASA low outgassing specifications. |