Master Bond has developed many dielectric and conductive surface mount adhesive systems (SMAs) for use in various electronic applications. These can be either one component compounds which cure with heat or two component chemistries which can cure at room temperature. Electrically insulating surface mount adhesives offer excellent bond strength and can hold components in place during solder reflow process. Electrically conductive SMAs are employed in various advanced electronic devices to replace solder.

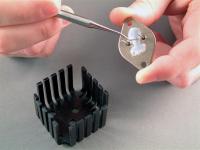

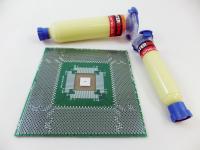

Selecting the most suitable formulation is dependent on the size/type of components, application conditions, curing & processing requirements, and dispensing needs. Common application methods include screen printing and syringe/needle dispensing.

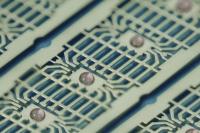

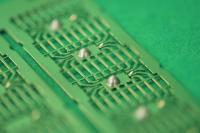

These products offer no tailing, limited flow after component placement, low moisture absorption, wide operating temperature range, excellent resistance to mechanical shocks and vibrations, and high physical strength properties.

Performance Properties of Master Bond’s Surface Mount Adhesives

Some of the most important performance properties are:

- Thermally conductive/electrically insulativing

- Electrically conductive

- Consistent dot profile

- Non corrosive

- Void filling

- Withstand thermal stress

- No stringing

- Color coded as required

Learn about our silver conductive surface mount adhesives designed to replace solder pastes

Common Applications Featuring Master Bond’s Surface Mount Epoxies

These versatile products are used extensively by leading electronics, automotive, medical, aerospace, and specialty OEM companies. They have successfully satisfied stringent specifications and standards for use by these organizations. Automated application of surface mount adhesives have enabled accurate, effective dispensing in tight spaces enabling design engineers new product opportunities with enhanced functionality and high yields. Some examples are:

- Chip on board assemblies

- Analog devices

- X-ray and imaging equipment

- Electro-optical sensory devices

Most Popular Surface Mount Epoxies

|

Supreme 3HTND-1SM One part, oven curing system (cures at 125-150°C) with rapid curing. Good physical properties. Paste consistency. Recommended for surface mounting. Void filling. Low ioinic impurities. Superior "green" strength. No stringing. Withstands thermal stress. Consistent dot profile. Can be automatically dispensed for high volume applications. Serviceable from -100°F to +350°F. |

|

EP21TDCHT High strength, high temperature resistant, two part system with excellent bond strength and thermal cycling capabilities. Serviceable from -100°F to +350°F. Meets MIL-STD-883J Section 3.5.2 for thermal stability. Moderate viscosity. Superior toughness. Withstands vibration, impact, shock. Good dimensional stability. Convenient one to one mix ratio. Dependable electrical insulation properties. |

|

Supreme 11AOHT Thermally conductive, electrically insulative epoxy adhesive. Meets MIL-STD-883J Section 3.5.2 for thermal stability. High peel and shear strength properties. Non-drip system. Resists -112°F to +400°F. Toughened system. Can withstand rigorous thermal cycling. Convenient one to one mix ratio by weight or volume. Cures at room temperature. |

|

Supreme 3HTND-2DA One component, fast curing die attach adhesive. Excellent die shear strength. Serviceable from -100°F to +400°F. Low ionics. Superior thermal conductivity and electrical insulation properties. Dispenses smoothly without tailing or bleed out. Cures in 5-10 minutes at 150°C. NASA low outgassing approved. Available in syringes. Well suited for automatic dispensing. Performed well in 85°C/85% RH testing. |

|

EP17HTDA-1 Single component heat curable epoxy adhesive/sealant. Non-drip system. Resists up to 525°F. Meets NASA low outgassing specifications. Meets MIL-STD-883J Section 3.5.2 for thermal stability. High lap shear, tensile and compressive strength. Tg of 230-240°C after post cure. |

|

EP3HTSDA-2 Silver filled electrically conductive epoxy has a rapid cure speed. Low volume resistivity and high temperature resistance. Superior bond strength. Thermally conductive with incredibly low thermal resistance. Smooth paste, consistency. Available in syringes that are compatible with various types of automatic dispensers or manual dispensing. Serviceable from -80°F to +450°F. |