Master Bond’s dimensionally stable systems are designed for long-term durability and high performance even in extreme environmental conditions. These formulations consist of epoxies, silicones, polyurethanes, polysulfides and UV curable systems.

Applications of Dimensionally Stable Adhesives and Potting Compounds

Master Bond's dimensionally stable systems are employed in many high tech industries. They can be used in a variety of applications, including:

- Semiconductor assembly

- Optoelectronic packaging

- Industrial switchgear applications

- Potting of high voltage sensors

Utilization of these products has enabled end users to ensure exact positioning/alignments improving quality, enhancing dependability under demanding conditions. Most importantly, filled epoxy adhesive systems have a low degree of shrinkage in comparison to other adhesive systems. While unfilled systems have proven successful in offering low shrinkage, often inorganic fillers have been incorporated in epoxy adhesives to lower shrinkage further. Consideration of stress from thermal expansion mismatches is another factor of significance when selecting a dimensionally stable adhesive.

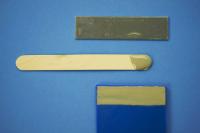

The table below illustrates the coefficient of thermal expansion, hardness and service temperature range properties that can be achieved for the systems noted:| System Type | Product | CTE, 75°F, x 10-6 in/in/°C | Shore D Hardness, 75°F | Service Temperature Range |

|---|---|---|---|---|

| Two part epoxy | EP30LTE-LO | 15-18 | 85-95 | 4K to 250°F (4K to 121°C) |

| One part UV cure | UV22DC80- 10F | 30-35 | 75-85 | -60°F to 350°F (- 51°C to 177°C) |

| Two part epoxy | EP21TCHT-1 | 18-21 | 85-95 | 4K to 400°F (4K to 205°C) |

| Two part epoxy | EP30-2 | 40-45 | 80-90 | 4K to 300°F (4K to 149°C) |

| Two part epoxy | EP30NS | 30-35 | 80-90 | -60°F to 300°F (-51°C to 149°C) |

Some of Our Most Popular Dimensionally Stable Epoxy Adhesives

|

Supreme 10AOHT-LO Thermally conductive and electrically insulative, one part epoxy adhesive. Superior toughness and dimensional stability. Bonds are resistant to thermal cycling and many chemicals. Serviceable from 4K to +400°F. NASA low outgassing approved. Withstands 1,000 hours 85°C/85% RH. Impressive physical strength properties. |

|

EP21AN Thermally conductive/electrically insulative epoxy. Two part system cures at ambient temperatures. Has convenient one to one mix ratio by weight or volume. Excellent heat transfer characteristics. High bond strength. Shore D hardness 85-90. Low coefficient of expansion. Serviceable from -60°F to +250°F. |

|

EP13 One component, heat curable epoxy adhesive. Serviceable from -60°F to +500°F. Paste viscosity. High tensile shear and compressive strength. Chemical resistant. Machinable. |

|

EP30 Low viscosity two part high performance epoxy resin system. High strength rigid bonds. Low linear shrinkage after cure. Superb optical clarity and light transmission properties. Serviceable from -60°F to +250°F. Cures readily at room temperature. Withstands 1,000 hours 85°C/85% RH. |

|

EP21QF Two component, moderate viscosity epoxy. The service temperature range is -80°F to +300°F. Color coded for easy mixing. Good physical strength profile. |

|

EP30-1NV Low viscosity two part high performance epoxy resin system. High strength rigid bonds. Low linear shrinkage after cure. Superb light transmission properties. Serviceable from -60°F to +250°F. Cures readily at room temperature. |

|

EP33ND Non-drip thixotropic epoxy paste. Demonstrated radiation stability at high radiation dosages. Serviceable from -60°F to +450°F. Gap filling. One to one mix ratio by volume. Adheres well to similar and dissimilar substrates. Cures at ambient temperatures. Post cure to optimize properties. Readily machinable. |