Specially developed adhesives, sealants, conformal coatings and encapsulation compounds have been formulated for the assembly of medical electronic devices. These products consist of one and two component epoxy systems, one and two part silicone compounds, cyanoacrylate and UV curable formulations. These technologically advanced materials offer high reliability, easy processing. and have been tested to meet ISO 10993-5 cytotoxicity and USP Class VI requirements.

Types of Compounds for the Assembly of Medical Devices

Medical electronic devices have greatly enhanced the ability to diagnose, treat and monitor different medical conditions. Master Bond offers the following flexible/semi-flexible/rigid products in low/medium, paste viscosity to meet these critical needs. The most noteworthy feature:

- Electrically conductive pastes

- Electrically insulative pastes

- Thermally conductive/electrically insulative pastes

- Glob top coatings

- Conformal coatings

- Underfill encapsulants

Specific grades feature:

- Low stress

- Low outgassing

- Snap cures

- Ultra low moisture absorption

- Optical clarity

Medical Electronic Coatings and Potting Compounds

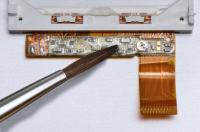

Low viscosity one part UV/Visible light cure systems have led the way featuring fast cure speeds upon UV light exposure, superb electrical insulation properties and outstanding physical strength. These low shrinkage formulations contain no solvents and adhere well to a wide range of substrates such as glass, FR4, ceramics, metals, polystyrene, polyurethane. Dual cure formulations have a secondary heat curing mechanism for "shadowed out" areas. These cures can be achieved at 80°C and dual cure products have a high Tg after post curing. Select grades have superior flexibility/toughness, withstand abrasion, aggressive chemicals, repeated sterilization. LED compositions are ideal for bonding to heat sensitive substrates and are tack free after cure. Two component thermally conductive/electrically insulative biocompatible epoxy systems exhibit dimensional stability, a low coefficient of thermal expansion, a flowable consistency and impressive dielectric characteristics for potting/encapsulation. Other epoxy compounds have been designed to withstand multiple repeated cycles of autoclaving, high thermal stability and can be castable in thicknesses exceeding 2-3 inches.

Applications for Master Bond Medical Electronic Device Compounds

Master Bond formulations are employed in a wide range of medical electronic device applications including:

- Hearing aids

- Drug releasing pumps

- Defibrillators

- Fetal and maternal monitors

- Fingertip pulse oximeters

- Neurostimulators

Some of Our Most Popular Medical Electronic Device Compounds

|

EP21TDCSMed Silver conductive epoxy with low volume resistivity and USP Class VI certification. Cures at room temperature or more quickly at elevated temperatures. Durable. Serviceable from 4k to +250°F. Smooth paste. One to one mix ratio by weight or volume. Shore D hardness 50-60. High bond strength. |

|

MasterSil 151Med Medical grade, USP Class VI approved silicone. Addition type cure system. Optically clear. Low outgassing. Offers ambient or elevated temperature cures. Excellent for potting and encapsulation applications. Low shrinkage upon cure. Resists gamma radiation, EtO and various chemical sterilants. Serviceable from -65°F to +400°F. |

|

EP42HT-2ND-2Med Black Two component epoxy paste adhesive. Resists sterilization exposure. USP Class VI approved. Outstanding thermal stability and electrical insulation properties. Cures at ambient temperatures. Withstands multiple cycles of autoclaving, radiation, EtO and chemical sterilants. Post curing is recommended to optimize physical properties. Serviceable from -60°F to +450°F. |

|

EP3HTSMed One part, silver conductive epoxy adhesive. USP Class VI approved. Rapid cures at elevated temperatures. Thixotropic paste. Serviceable from -60°F to +400°F. High shear strength. Excellent thermal and electrical conductivity. Exceptionally low resistivity. |

|

EP30DPBFMed Epoxy-urethane blend. Superior toughness and abrasion resistance. Biocompatible. Cryogenically serviceable. Low viscosity. Low moisture absorption and hydrolytic stability. USP Class VI approved. Serviceable from 4k to +250°F. Outstanding electrical insulation properties. Withstands thermal cycling. High impact strength. |

|

EP77M-FMed Rapid room temperature curing silver filled electrically conductive adhesive. One to one mix ratio by weight or volume. Fixture time within 5-7 minutes even in small volumes. Exceptional low volume resistivity. Low outgassing. Superior bond strength to similar/dissimilar substrates. Serviceable from -60°F to +250°F. |