Cutting edge adhesive formulations are available for bonding glass to glass and to numerous other substrates including plastics, metals, and rubbers. These compounds are available as epoxies, silicones, polyurethanes, polysulfides, cyanoacrylates and UV/LED curing systems. They are designed to provide optimal performance even upon exposure to hostile conditions.

Key benefits of Master Bond's glass bonding adhesives

Master Bond's glass bonding adhesive systems are easy to apply and feature high strength bonds. Different grades include:

- One and two part systems

- Solvent free compositions

- Optical clarity

- Non-yellowing properties

- Moisture resistance

- Thermal stability

- Toughness

- Chemical inertness

Select formulations exhibit good wetting characteristics, low shrinkage, superior impact/vibration resistance and stress absorption when bonding materials with different coefficients of thermal expansion. A range of viscosities/cure speeds are available to improve efficiency, productivity and cost effectiveness. Compounds are engineered to adhere well to different types of glass such as borosilicate, fused quartz, glass ceramic and glass fiber surfaces. Products exhibit outstanding long term durability even upon exposure to hot, cold, humid environments.

Master Bond structural glass bonding/laminating systems are used in the appliance, electronic, optical, medical diagnostic, military/defense, automotive and specialty OEM industries. Specific applications range from oven doors to computer screens to LED display lamps to astronomical telescopes to vehicle sunroof assembly.

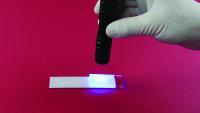

Master Bond has developed single component LED curable adhesives for rapid bonding of tinted/UV blocked glass surfaces. These systems cure tack free, have excellent light transmission properties, low energy consumption and consistent process control with uniform intensity output.

Surface preparation for glass substrates

Even though glass substrates have high surface energy and can be easily wet, it is important to carry out the necessary surface preparation in order to optimize adhesion to different substrates. Typically, degreasing the substrates would help improve their bond strength. However, depending on the ultimate strength required, mechanical abrasion can also be carried out using emery paper or sand blasting. A combination of cleaning and mechanical abrasion can also be employed for optimum results. Please note that it is not recommended to mechanically abrade optical glass, since it can effect its light transmission properties.

Most Popular Glass Bonding Polymer Systems

|

UV10 One component, no mix, UV curable adhesive. High strength bonds and superior chemical resistance properties. Low viscosity. Excellent dimensional stability. Fast curing. Serviceable from -60°F to +300°F. |

|

UV15 Low viscosity, rigid UV curable system with superb thermal stability. Also capable of spin coating. Outstanding optical clarity. High bond strength. Serviceable from -80°F to +350°F. |

|

EP30 Low viscosity two part high performance epoxy resin system. High strength rigid bonds. Low linear shrinkage after cure. Superb optical clarity and light transmission properties. Serviceable from -60°F to +250°F. Cures readily at room temperature. Withstands 1,000 hours 85°C/85% RH. |

|

Supreme 11HT High peel and shear strength system. Convenient one to one mix ratio. Serviceable from -100°F to +400°F. Superior resistance to impact, thermal shock, vibration and stress fatigue cracking. Excellent toughness. Cures readily at room temperature. User friendly. Dependable dimensional stability. Readily machinable. |

|

EP30-2 Cryogenically serviceable. NASA low outgassing approved. 100% reactive. Excellent light transmission properties. Outstanding dimensional stability. High tensile and compressive strength. Successfully tested for 1,000 hours 85°C/85% RH. Excellent dielectric properties. Serviceable from 4k to +300°F. |

|

UV10-FD One component, UV curable adhesive contains a flourescent dye for identification. High strength bonds and superior chemical resistance properties. Low viscosity. Excellent dimensional stability. Fast curing. Serviceable from -60°F to +300°F. |