High performance complex automated semiconductor equipment meet exacting standards and enable electronic device manufacturers to assemble smaller, smarter, faster, more powerful, affordable products that require lower power consumption. Master Bond adhesives, sealants, coatings, potting/encapsulation compounds consisting of epoxies, silicones have been instrumental in contributing solutions to enhance innovation, maximize productivity while decreasing defects. Master Bond is leading the way in semiconductor packaging with a complete line of underfill, die attach, glob top and encapsulation compounds. These systems are designed for easy processing and dependability.

Collaborating with both suppliers and customers, Master Bond's team of technical experts has played a key role in the development of cutting edge semiconductor equipment used for etching, cleaning, deposition, photolithography, diffusion to assembly, packing, testing systems. Upgrading manufacturing technology is extremely important in this most competitive industry. Our engineering staff has encountered many difficult technical challenges and has been successful in blending unique formulations to satisfy difficult specification requirements.

Employing many Master Bond polymeric compositions has provided semiconductor equipment companies design flexibility, reduction in lead times, increased output, lower costs and new opportunities to create technically advanced products at healthy operating margins. Major progress has facilitated smaller geometry chip designs, larger diameter silicon wafers and a transition from aluminum to copper interconnecting. Growing markets for mobile technology, internet of things, rising storage needs will expand the scope of possibility in the digital economy and the anticipated future demand for appropriate semiconductor equipment to keep pace with the ever evolving rapid pace of change. The proliferation in the use of electronic devices will only heighten the significance in the capability of these most vital lines of semiconductor equipment products.

Most Popular Adhesives for the Semiconductor Industry

|

UV15X-2GT One part, UV curable epoxy with ultra fast curing. Good physical properties and chemical resistance. Used for glob top applications. Thixotropic paste viscosity. Excellent toughness. Withstands thermal cycling. Shore D hardness 65. Serviceable from -80°F to +250°F. |

|

EP30FL Low viscosity, optically clear epoxy. Ideal for thermal cycling and bonding sensitive components. Room temperature or low elevated temperature cure. Good flexibility. Superb impact resistance. Shore D hardness 25-40. Serviceable from 4k to +250°F. |

|

EP79 Cost effective alternative to silver filled epoxy with a silver coated nickel filler. Excellent conductivity and physical properties. Superior durability and thermal cycling capabilities. Cures readily at room temperature. Convenient one to one mix ratio weight or volume. Superb heat dissipation. Low linear shrinkage upon cure. Withstands 1,000 hours 85°C/85% RH. Serviceable from 4k to +275°F. Available in premixed and frozen syringes. |

|

EP3RRLV One part oven cured system (125-150°C) for potting, encapsulation and underfill applications. Good dimension stability and very easy to use. Cures rigid. Thermally conductive/electrically insulative. Excellent flow properties. Superior mechanical strength. Can be cast up to 1 inch thick. Withstands 1,000 hours 85°C/85% RH. Serviceable from -60°F to +350°F. |

|

EP30LTE Thermally conductive, electrically insulative epoxy. Has low thermal expansion coefficient. Superior dimensional stability. Good flow properties. Exceptionally low shrinkage upon cure. Service operating temperature range from -100°F to +250°F. Adheres well to similar and dissimilar substrates. |

|

Supreme 10HTS Silver filled system with excellent electrical conductivity and high physical strength properties. One part, heat cured (250-300°F) epoxy. Wide range of serviceability from cryogenic temperatures up to +400°F. Meets NASA low outgassing specifications. Can be applied without sagging or dripping, even on vertical surfaces. Volume resistivit <0.006 ohm-cm. Thermally conductive. Shore D hardnes >75. |

|

EP37-3FLF Highly flexible, low viscosity, optically clear adhesive. Resistant to severe thermal cycling and thermal shock. Bonds well to dissimilar substrates. Low exotherm system. Long working life. Superior electrical insulation properties. Service temperature range from 4K to +250°F. One to one mix ratio by weight or volume. |

|

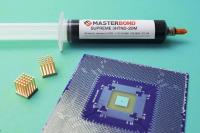

Supreme 3HTND-2DM Toughened epoxy paste system for damming applications. Requires no mixing. Rapid heat curing. Passes NASA low outgassing testing. Transfers heat efficiently. Stellar electrical insulation properties. Serviceable from -100°F to +400°F. |