One part, low viscosity UV curable system featuring high temperature resistance for bonding, sealing and coating

Key Features

- Excellent physical strength properties

- High glass transition temperature

- Superb chemical resistance

- No oxygen inhibition

- Meets NASA low outgassing specifications

Product Description

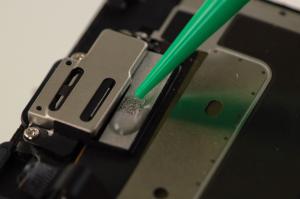

Master Bond UV26SP is a one part UV curing system for bonding, sealing and coating. UV26SP cures exceptionally quickly when exposed to UV light emitting at a wavelength of 320-365 nm with an energy output as low as 20-40 milliwatts per cm². UV26SP is highly exothermic. It cures very quickly and should not be cured in sections thicker than .004 to .005 inches. It should be noted that when bonding, a thickness of .001 to .002 inches is more than adequate. Most important, UV26SP is not oxygen inhibited.

The system bonds well to glass, surface treated metals, and many plastics including polycarbonates and acrylics. UV26SP is not only effective as an adhesive, but also as a coating and sealant. It is able to withstand acids, bases, fuels, and many aggressive solvents far better than most other UV systems. Its glass transition temperature is 160 to 170°C, considerably higher than other UVs. This system does not contain any solvents or volatiles and features low shrinkage upon curing. Its service temperature range is -60°F to +500°F.

UV26SP is a specialty type UV curable with advantageous chemical and temperature resistance, thus, it is a prime candidate for applications in aerospace, electronic, optical, specialty OEM and related industries.

Product Advantages

- Fast cure upon exposure to a UV light

- No oxygen inhibition while curing

- Very good adhesion to a variety of substrates

- Outstanding optical clarity

- Top notch chemical and temperature resistance

Industrial Certifications

Packaging

UV26SP is available is various sizes and units to accommodate customer's needs.