Achieve optimal bond strength with proper surface preparation of your metal. We’ll demonstrate how in this captivating video.

Video Transcript

Thank you for joining us. Today we are going to demonstrate how proper preparation of a metal surface can ultimately determine how effective the bond strength of your application will be. Let's start by applying a drop of water to this metal strip and see what happens.

The drop of water is beading, which means that the surface is not properly prepared and may contain a contaminant like paint, lubricating oil, or grease.

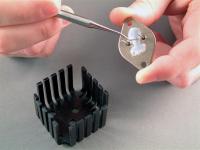

Next, let's roughen the metal strip with a piece of sandpaper. Then, we'll degrease the surface with acetone. Again, we will apply a drop of water to see what happens.

Now the water is spreading, which means that the surface has been prepared and the adhesive is ready to be applied.

There are three major methods for removing surface contaminants--degreasing, chemical cleaning and abrasion. For the best results, using a combination of these techniques may be recommended.

Here is a bonded joint that was not properly roughened and contaminated before bonding. You can see that the adhesion is not good. Here is a piece that was properly roughened and cleaned before bonding with a two part room temperature curing adhesive. Clearly, it's much stronger. In many applications, proper surface preparation is essential to optimize bond strength for long term performance and durability. Thanks for watching. Please contact our technical advisors for more information.

Disclaimer: When using recommended chemicals follow appropriate federal, state and local regulations for safe handling and disposal. Appropriate care is required when carrying out necessary surface preparation procedures.

Popular Metal Bonding Adhesives

|

Supreme 10HT One part structural epoxy with high bond strength and excellent adhesion to similar and dissimilar substrates, especially composite materials. Requires oven curing at 250-300°F. NASA low outgassing approved. Serviceable from 4k to +400°F. Tough and durable. 85°C/85% RH resistance. |

|

EP21TDCHT High strength, high temperature resistant, two part system with excellent bond strength and thermal cycling capabilities. Serviceable from -100°F to +350°F. Meets MIL-STD-883J Section 3.5.2 for thermal stability. Moderate viscosity. Superior toughness. Withstands vibration, impact, shock. Good dimensional stability. Convenient one to one mix ratio. Dependable electrical insulation properties. |

|

FLM36-LO NASA low outgassing approved B-stage epoxy adhesive. Tough and flexible. Elongation is greater than 50%. Thermally conductive/electrically insulative. Withstands rigorous thermal cycling. Can be die cut into custom shapes. Squeeze out is minimal. Ideal for applications requiring precise bond lines. Resists up to +500°F. |

|

EP31ND Non-drip structural epoxy adhesive. Paste consistency. Gap filling. Unmatched peel and shear strength. Tough and resilient. Protects against exposure to water, oil, fuels. Cures at room temperature. Service temperature range from -60°F to +250°F. |

|

Supreme 11AOHT Thermally conductive, electrically insulative epoxy adhesive. Meets MIL-STD-883J Section 3.5.2 for thermal stability. High peel and shear strength properties. Non-drip system. Resists -112°F to +400°F. Toughened system. Can withstand rigorous thermal cycling. Convenient one to one mix ratio by weight or volume. Cures at room temperature. |