Master Bond is a supplier of technologically advanced structural adhesives, sealants, coatings, thermal management materials, vacuum impregnation compounds, and conductive coatings that can be utilized for new lithium battery designs. Plug-in electric vehicles such as motorcycles, buses, trucks, passenger cars are being built globally at a rapid pace to meet increased demand. They have gained popularity because these battery electric vehicles (BEV) are environmentally friendly, emit zero exhaust emissions, improve air quality, eliminate fuel expenses, diminish traffic noise, have faster acceleration, and require less frequent maintenance. Some key priorities for EVs are to engineer more compact, lightweight batteries with higher energy density, prevent overheating and bolster high volume production speeds.

Master Bond is a supplier of technologically advanced structural adhesives, sealants, coatings, thermal management materials, vacuum impregnation compounds, and conductive coatings that can be utilized for new lithium battery designs. Plug-in electric vehicles such as motorcycles, buses, trucks, passenger cars are being built globally at a rapid pace to meet increased demand. They have gained popularity because these battery electric vehicles (BEV) are environmentally friendly, emit zero exhaust emissions, improve air quality, eliminate fuel expenses, diminish traffic noise, have faster acceleration, and require less frequent maintenance. Some key priorities for EVs are to engineer more compact, lightweight batteries with higher energy density, prevent overheating and bolster high volume production speeds.

Master Bond is diligently working on developing innovative epoxy and silicone systems that can be employed to help lithium-ion battery manufacturers to optimize performance, safety, and protection form water, dust, road salt, extreme temperatures, shock, and vibration. High quality, customized adhesive formulations can provide longevity, offer outstanding dielectric properties, and are capable of resisting stress, inclement weather, and temperature fluctuations. They can also confer flame retardancy, corrosion as well as thermal cycle resistance, while eliminating heavy mechanical fasteners. Durable toughened compositions can bond well to a wide variety of similar/dissimilar substrates. They can also be utilized as proficient gap fillers which can be designed to be compatible with cylindrical, pouch, prismatic battery cells. Most importantly structural Master Bond one and two component adhesive systems can be used to attach battery cells, modules, and packs. Specialty systems are engineered to provide remarkable thermally conductive characteristics to satisfy arduous cooling requirements.

Leading the way in solving complex, and stringent specifications are numerous unique Master Bond compositions. These products can be used for the assembly of lithium-ion batteries. Some prominent application where they may be applied include but are not limited to bonding/sealing battery packs/modules, cells into modules, cells to cooling plates, cell encapsulation, gasketing, structurally bonding battery pack covers, battery box structural bonding/sealing, cell to frame bonding, module encapsulation, flame retardant coating of packs, gap fillers for thermal management of battery packs, structural bonding within battery packs, battery frame and cage adhesives.

Many cutting-edge Master Bond grades can prove to be instrumental in delivering impressive results in the construction of lithium-ion batteries. These liquid systems exhibit exceptional heat transfer and impressive electrical insulation when employed in numerous vital endeavors. They often contain different type, sizes, shapes, amounts of fillers that enhance their ability to perform successfully under the most rugged, aggressive conditions. Master Bond EP29LPTCHT is one of the most preferred two component systems recommended for mechanical stability, enhanced thermal dissipation, versatility, and environmental protection. This low viscosity, flowable composition is adept at filling air gaps and can be applied in sections as thin as 10-15 microns.

EP29LPTCHT has low shrinkage upon cure, superb dimensional stability, a low coefficient of thermal expansion and passes NASA low outgassing test. It is capable of providing a thermal resistance as low as 12-15 x 10-6 km-2/W, which is much lower than standard thermal conductive epoxies. Single component epoxy Master Bond EP5TC-80 cures at moderate elevated temperatures and requires no mixing. It features superior adhesion between similar/dissimilar substrates and outstanding thermal conductivity a > 3 W/(m·K) along with excellent electrical insulation. This compound contains ultra fine particles, and can cure at temperatures as low as 80°C.

EP29LPTCHT has low shrinkage upon cure, superb dimensional stability, a low coefficient of thermal expansion and passes NASA low outgassing test. It is capable of providing a thermal resistance as low as 12-15 x 10-6 km-2/W, which is much lower than standard thermal conductive epoxies. Single component epoxy Master Bond EP5TC-80 cures at moderate elevated temperatures and requires no mixing. It features superior adhesion between similar/dissimilar substrates and outstanding thermal conductivity a > 3 W/(m·K) along with excellent electrical insulation. This compound contains ultra fine particles, and can cure at temperatures as low as 80°C.

Another widely used legacy epoxy system is Master Bond EP21TCHT-1. It has a thixotropic paste consistency, cures at room temperature or more rapidly at elevated temperatures and is serviceable from 4 Kelvin to +400°F. EP21TCHT-1 can withstand 1,000 hours at 85°C/85%RH, passes MIL-STD-810G for fungus resistance, and withstands exposure to many chemicals. This formula has a low coefficient of thermal expansion and has extraordinary compressive strength of 22,000-24,000 psi.

One component, moisture curing, non- corrosive silicone Master Sil 705TC is a paste, has a fast tack-free time, an elongation of around 70% and a Shore A hardness of 70-80. It is serviceable up to 400°F, has excellent dielectric strength and offers excellent resistance to aggressive thermal cycling.

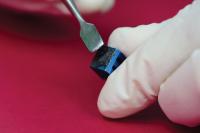

It is particularly noteworthy that most of these compounds were engineered so they could be dispensed via automated equipment to streamline processing and boost productivity. Automated dispensing of adhesives, sealants, gasketing materials, potting compounds for assembling lithium-ion batteries have enabled compositions with different thicknesses to be applied accurately, consistently, precisely, safely, without material wastage. They have heightened quality control and can provide outstanding fatigue resistance.

Cutting edge electrically and thermally conductive Master Bond products feature remarkable heat transfer properties. Some Master Bond grades are as follows:

- EP3HTS-TC – 16-17 W/(m·K)

- EP3HTSDA-2 – 6.5-7 W/(m·K)

- EP30NG – 5.5 W/(m·K)

- EP5G-80 – 2.88-3.46 W/(m.K)

Master Bond is actively pursuing projects to prevent lithium-ion battery degradation. The amount of energy a battery can store over time, the effect of usage, temperature exposure, high/low state of charge are of great significance. These issues need to be addressed to evaluate efficiency and aging phenomena. Circumventing premature replacement of batteries is advantageous in avoiding consumption of new materials (ecologically friendly) and lowers car maintenance expenses. Several Master Bond compounds can provide valuable contributions to motors, motor inverters, EV chargers, on-board chargers, sensors, controls, and transformers used in electric vehicles.

Master Bond Popular Products

|

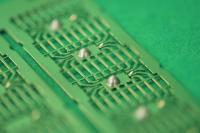

EP3HTS-TC Silver filled electrically conductive, for die attach and general bonding. Low volume resistivity and high temperature resistance. Superior bond strength. Thermally conductive. Thixotropic paste, consistency. Available in syringes that are compatible with various types of automatic dispensers or manual dispensing. Serviceable from -80°F to +400°F. |

|

EP3HTSDA-2 Silver filled electrically conductive epoxy has a rapid cure speed. Low volume resistivity and high temperature resistance. Superior bond strength. Thermally conductive with incredibly low thermal resistance. Smooth paste, consistency. Available in syringes that are compatible with various types of automatic dispensers or manual dispensing. Serviceable from -80°F to +450°F. |

|

EP30NG Graphene filled epoxy. Non-drip system for bonding and sealing. Cures at room temperature. Superior abrasion resistance. |

|

EP5G-80 Graphite filled epoxy that cures at 80°C. Good electrical and thermal conductivity. Passes NASA low outgassing certification. Can be used for bonding, sealing, coating. Service temperature range is -50°C to +175°C |