Expanded Product List

Master Bond Product Search

188 products match

|

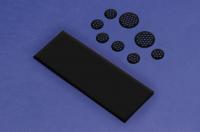

FLM36 B-staged film adhesive/sealant. Outstanding thermal cycling capabilities and structural properties. Offers superior toughness and flexibility. Excellent strength retention at elevated temperatures. Thermally conductive/electrically insulative. Provides uniform bond line thickness. Serviceable from -100°F to +500°F. Preforms are available. |

|

FLM36-LO NASA low outgassing approved B-stage epoxy adhesive. Tough and flexible. Elongation is greater than 50%. Thermally conductive/electrically insulative. Withstands rigorous thermal cycling. Can be die cut into custom shapes. Squeeze out is minimal. Ideal for applications requiring precise bond lines. Resists up to +500°F. |

|

MasterSil 151AO Thermally conductive silicone casting, potting and sealing system. Thermal conductivity of 0.35-.0.54 W/(m•K). Electrically isolating. Low viscosity system bonds well to a wide variety of substrates. Remarkable flexibility. Temperature resistant from -65°F to +400°F. White color. |

|

MasterSil 151S Addition curing, two part silicone for use as an adhesive, sealant, coating or form-in-place gasketing material. Despite its silicone chemistry, it passes NASA low outgassing specifications. It is ideal for applications where low stress is required. |

|

MasterSil 151TC Optically clear, addition curing potting, encapsulation, sealing compound. Low shrinkage upon cure. Resists up to +400°F [+204°C]. Shore A hardness 50-60. Highly resistant to water. Long pot life. Primarily in thermal management applications. |

|

MasterSil 155 Two part, graphite filled silicone adhesive. Convenient one to one mix ratio by weight. Volume resistivity 20-40 ohm-cm. Elongatio >300%. Serviceable from -85°F to +400°F. |

|

MasterSil 156 Two part silicone potting/encapsulation compound. Superior thermal conductivity. High elongation. Long pot life. Cures in thicknesses beyond 1-2 inches. UL 94V-0 flame retardant system. Serviceable from -65°F to +221°F. |

|

MasterSil 323S-LO Addition curing, two part silicone for use as an adhesive, sealant, coating. Passes NASA low outgassing specifications. Serviceable from -80°F to +400°F. Electrically conductive with convenient processing. |

|

MasterSil 705C Single component, electrically conductive, non-corrosive silicone compound. Carbon filled. Tack free time 3-7 minutes at ambient temperatures. Paste viscosity. Serviceable up to 400°F. |

|

MasterSil 705S Silver filled, one-part, no-mix, non-corrosive silicone system. Shore A hardness 70. Cures at room temperatures when exposed to atmospheric moisture. Extremely low volume resistivity. Most effective when applied in thin sections. |