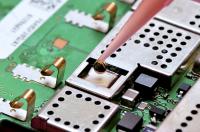

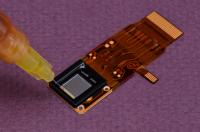

Master Bond liquid gel compounds consist of urethane modified epoxy systems, silicones and UV curable acrylates. These eco-friendly low stress formulations are designed to provide reliable, long term protection for sensitive electronic components/assemblies. Low modulus and ultra low modulus low/medium/thixotropic paste viscosity systems have proven effective for potting/encapsulation of PCB's, PV solar junction boxes, automotive sensors, power modulus, high voltage electrical components, industrial/military devices. They offer exceptional resistance to vibration, impact, shock, temperature fluctuations, moisture, dust, dirt, environmental contaminants. Flexible/resilient gels also possess outstanding dielectric properties, low shrinkage, easy repairability/retrievability and withstand exposure to oils, fuels, solvents. Select grades were developed to feature high/low temperature serviceability, optical clarity, thermal conductivity, flame resistance, low amount of ionic impurities and to adhere to difficult to bond to surfaces.

Shore A Hardnesses of One and Two Part Adhesive Gels

Two component, room temperature curing urethane modified epoxy gels are soft and have a low Shore A hardness of 5-10. These multi-function compositions exhibit high dimensional stability, long working life after mixing (7-9 hours for a 100 gram mixed batch), low exotherm and can be cast in sections up to 2-3 inches thick. They also have highly desirable accoustical damping properties. A thermal conductive grade features superior heat dissipation characteristics, bonds well to a wide array of substrates and has extraordinary thermal/mechanical shock resistance. An optically clear formula has a refractive index of 1.52 for use in optical/electro optic devices.

Master Bond single component, no mix UV curable acrylate gels are noted for their quick cure speeds and low energy consumption. These low viscosity compositions have good flow and contain no solvents. Products have high optical clarity/excellent light transmission properties. They are serviceable from -60°F to +250°F. Compounds are electrical and thermal insulators. Master Bond UV21 can cure sections approaching 1/4 inch thick. In contrast Master Bond UV19 has a Shore A hardness of 10-15 but is recommended only for thin bond lines of only 0.001"/0.003".

Serviceability, Curing, Certifications and Other Properties of Adhesive Gels

Master Bond's broad line of extra soft/soft water-repellent silicone gels have impressive high/low temperature capability. Serviceability can range from -75°F to +572°F (300°C). They provide stress relief, self healing properties and deliver protection against corrosion under hostile environmental conditions. These low and ultra low modulus gels retain their electrical insulative/bonding characteristics even while damping mechanical vibration and withstanding exposure to thermomechanical stresses. Products extend from single component, non-corrosive fast room temperature curing formulas to addition cured two component systems with convenient mix ratios. Heat is often employed to accelerate cure for many silicone gels in deep sections with long working life. These products can be easily/rapidly dispensed in a wide variety of viscosities to cost effectively optimize productivity. Select grades are available that meet UL94V-1, UL94V-0 specifications, USP Class VI and ISO 10993-5 requirements and NASA low outgassing certifications. Additionally special non-yellowing, optical clear materials, MIL-A-46146 approved silicone gel and products that withstand 1,000 hours at 85°C/85%RH are obtainable to meet special needs.

Our Most Popular Flexibilized and Toughened Epoxy Compounds

|

Super Gel 9 Two part, room temperature curing, epoxy gel compound for sealing and encapsulation. Optically clear, soft and dimensionally stable. Ideal for retrievability. Two to one mix ratio by weight or volume. Low exotherm. Long working life. Low viscosity system. Unsurpassed thermal cycling and mechanical shock resistance. Used in conjunction with sensitive electronic and optical components. Serviceable from -100°F to +200°F. |

|

Super Gel 9AO Thermally conductive/electrically insulative urethane modified epoxy system. Soft and resilient. Solid dimensional stability. Easily repairable. Long working life. Low exotherm. Service temperature range -100°F to +200°F. Superior electrical insulation properties. Can be cast many inches in depth. Withstands thermal cycling and mechanical shock. |

|

MasterSil 170 Gel Two part, low viscosity silicone gel for sealing, potting and encapsulating applications. Outstanding flexibility. Superior electrical insulation properties. Exceptional optical clarity. Serviceable from -67°F to +392°F. |