Properties for aluminum alloys vary widely depending on the alloying elements. These include copper, magnesium, silicon, zinc, tin, scandium and titanium. They are available as casting alloys or wrought alloys (tubes, rods, rolled plate, foils). Both heat treatable and non-heat treatable aluminum alloys provide different physical properties to meet manufacturing specifications.

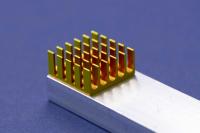

Aluminum alloys can offer superior tensile strength, high strength to weight ratio, outstanding fracture toughness, formability, workability and low temperature characteristics. They are used by the aerospace, automotive, marine, rail industries for lightweighting and improving energy efficiency. They are also used for machine components, packaging, appliances, energy distribution and in many engineering structures.

Epoxy and polyurethane adhesives are the systems of choice in bonding aluminum alloys. Concerns regarding formation of a protective layer of aluminum oxide and galvanic corrosion must be addressed to ensure suitability and compatibility of the bonding compound. Careful attention needs to be placed on following detailed surface preparation instructions to guarantee optimum adhesive performance.

Read our guide to learn more about proper surface preparation for bonding metals.

Master Bond Popular Products

|

Supreme 11ANHT High temperature resistant epoxy for bonding and sealing. Toughened formulation. Superior shear/peel strength. Excellent heat transfer properties. Superb dielectric characteristics, Serviceable from -112°F to +400°F. |

|

Supreme 45HTND-2LO Black Toughened, two component, non-drip epoxy paste. Service temperature range -100°F to +450°F. Long working life. Gap filling. Meets NASA low outgassing specifications. Withstands 1,000 hours 85°C/85% RH. Superior electrical insulator. Heat curing. |

|

Supreme 46HT-1AO Toughened epoxy system, resists thermal cycling. Serviceable from -100°F to +500°F. Exceptionally long working life. Thermally conductive, electrically insulative. |

|

EP45AOHT Thermally conductive/eletrically insulative epoxy serviceable from -60°F to +500°F. Heat curing. Paste viscosity. Superior chemical resistance properties. Gap filling. Long pot life. Withstands thermal cycling. Gray color. |