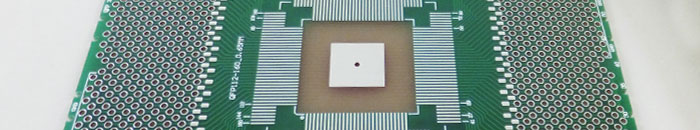

Master Bond's advanced die attach adhesives are increasingly accepted for demanding microelectronic semiconductor packaging as well as for chip on board assemblies. They offer outstanding bond strength for adhering components directly onto printed circuitry. These systems are presently employed in the assembly of many critical electrical devices used in commercial, military, space and medical applications.

Types of Die Attach Epoxies

Master Bond die attach adhesives are available in one component heat curing formulations and as B-staged epoxy films. They are designed to cure quickly for high volume production.

Outstanding Physical Properties of Die Attach Adhesives

Our high performance die attach compounds have many advantages, including:

- Excellent resistance to thermal cycling

- Mechanical shock and vibration resistant

- 100% reactive; they do not contain any volatiles

- Dimensional stability

- Low ionic impurities

- Adhesion to mismatched coefficients of thermal expansion

- Adjustable volume resistivity

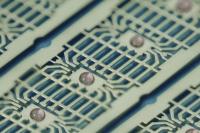

- Void free uniform bond lines

- Low humidity sensitivity

- Advanced heat dissipation characteristics.

Our ROHS compliant compositions can be used with a wide range of die sizes and exhibit outstanding die shear strength as shown in the following table.

| Die Shear Strength Testing Results for Thermally Conductive Adhesives | |||

|---|---|---|---|

| System Type | Product | Electrical Conductivity | Die Shear Strength @ 75°F 2x2 mm (80x80 mil) |

| Epoxy film | FL901AO | Electrically insulative | 40-42 kg-f |

| One part epoxy | EP17HTDA-1 | Electrically insulative | 24-27 kg-f |

| One part epoxy | Supreme 3HTND-2DA | Electrically insulative | 19-21 kg-f |

| Epoxy film | FL901S | Electrically conductive | 24-26 kg-f |

| One part epoxy | EP3HTSDA-1 | Electrically conductive | 20-22 kg-f |

| One part epoxy | EP3HTSDA-2 | Electrically conductive | 20-22 kg-f |

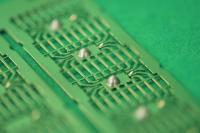

Die Shear Test Method

A small die is carefully mounted/attached on a lead frame with the help of an adhesive. The adhesive is typically dispensed (if liquid) or die cut and applied on the lead frame first. After mounting the die on the substrate, the adhesive is cured using the recommended cure schedule on the data sheet. Following this, a load applying instrument tries to shear (remove) the die from the lead frame by applying a force parallel to the lead frame (substrate). The point at which the die shears or breaks with the lead frame is then noted. This force is measured in kg-force needed to break the adhesive bond.

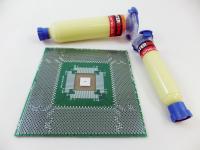

Die Attach Compounds Come in Convenient Packaging

These high performance epoxies can be readily dispensed by syringes and other conventional devices as well as by specialized printing technologies.

Some of Our Most Popular Die Attach Materials

|

Supreme 3HTND-2DA One component, fast curing die attach adhesive. Excellent die shear strength. Serviceable from -100°F to +400°F. Low ionics. Superior thermal conductivity and electrical insulation properties. Dispenses smoothly without tailing or bleed out. Cures in 5-10 minutes at 150°C. NASA low outgassing approved. Available in syringes. Well suited for automatic dispensing. Performed well in 85°C/85% RH testing. |

|

EP17HTDA-1 Single component heat curable epoxy adhesive/sealant. Non-drip system. Resists up to 525°F. Meets NASA low outgassing specifications. Meets MIL-STD-883J Section 3.5.2 for thermal stability. High lap shear, tensile and compressive strength. Tg of 230-240°C after post cure. |

|

EP3HTS-TC Silver filled electrically conductive, for die attach and general bonding. Low volume resistivity and high temperature resistance. Superior bond strength. Thermally conductive. Thixotropic paste, consistency. Available in syringes that are compatible with various types of automatic dispensers or manual dispensing. Serviceable from -80°F to +400°F. |

|

EP3HTSDA-2 Silver filled electrically conductive epoxy has a rapid cure speed. Low volume resistivity and high temperature resistance. Superior bond strength. Thermally conductive with incredibly low thermal resistance. Smooth paste, consistency. Available in syringes that are compatible with various types of automatic dispensers or manual dispensing. Serviceable from -80°F to +450°F. |

|

EP17HTDA-2 One component, heat cured epoxy for bonding and sealing, as well as die attach applications. Flowable, high viscosity system, cures in 4-5 hours at 300°F or 3-4 hours at 350°F. Post cure to optimize properties. High glass transition temperature. NASA low outgassing approved. |