Master Bond produces a variety of high performance adhesives for the assembly of composite products. Cutting-edge adhesive formulations are available for bonding fiber composites to themselves and numerous different substrates. These versatile adhesives are available as liquids, pastes and also as films to meet the modern day demand for composite bonding. They are designed to provide the highest mechanical strength and peerless performance even upon exposure to extreme conditions.

Performance Properties

The unique nature of the composites has made them extremely popular for high tech applications requiring lighter weight and higher strength. Bonded interfaces exhibit outstanding impact/fracture toughness, tensile, compressive, creep, stress fracture and shear capabilities. Other advantageous properties include resistance to thermal cycling, cryogenic shock resistance, low shrinkage, electrical insulation, resistance to chemicals, mechanical shock resistance and serviceability in extreme temperatures, to name a few.

Surface Preparation for Composites

Some of the most commonly used composites include carbon fiber, glass fiber, kevlar and graphite reinforced composites. Most often, these substrates are easily bondable. However, it is important to carry out the necessary surface preparation in order to ensure good bonding. Many times, composites are coated with a mold-release agent or a gel coat, which inhibits its ability to be bonded well to other substrates. Hence, thorough degreasing needs to be carried out to provide a surface free of any contaminants. Frequently, mechanical abrasion of the composites is also carried out to further improve its bond strength. However, caution must be exercised to make sure that the reinforcing fibers are not exposed or damaged while abrading. A combination of both techniques can also be carried out for optimum results.

Composites Bonding Best Practices

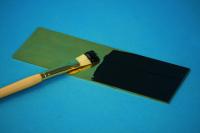

After preparing the surfaces, a uniform layer of the adhesive should be applied and the parts placed together. It is important to fixture the parts while the adhesive sets up to ensure good contact between the adhesive and the substrates. However, care should be taken to not apply excess pressure, to limit adhesive squeeze out from between the substrates. Film adhesives are ready to use and require no mixing. They provide a uniform bond line thickness and offer minimum flow while curing.

Typical Applications for Composite Adhesives

Master Bond custom formulates products with specific performance properties designed for unique applications where composite materials are used. Some examples of such applications include:

- Liquid shim epoxies for composites

- Adhesives for bonding of honeycomb sandwich panels

- Aircraft interior cabin

- Wind turbine blades

- Sports equipment

- Carbon fiber sports cars

- Medical prosthetics

- Tanks

These compounds have been successfully employed in aerospace, medical, optical, electrical, electronic and other manufacturing industries.

Most Popular Products for Composite Applications

|

Supreme 10HT One part structural epoxy with high bond strength and excellent adhesion to similar and dissimilar substrates, especially composite materials. Requires oven curing at 250-300°F. NASA low outgassing approved. Serviceable from 4k to +400°F. Tough and durable. 85°C/85% RH resistance. |

|

Supreme 33CLV Two component, room temperature curing structural epoxy system. Excellent bonding properties. Superior thermal cycling capabilities. Convenient one to one mix ratio by volume. Moderate viscosity. Toughened system. Outstanding resistance to water, fuels, various solvents acids and bases. Shore D hardness 75-80. |

|

EP46HT-2 Serviceable from -100°F to +500°F. Tg 155-165°C. Superior durability. Heat curing, two component epoxy compound. Resists thermal cycling. Withstands 1,000 hours 85°C/85% RH. Good electrical insulator. Ability to protect against hostile chemical exposure. |

|

FLM36 B-staged film adhesive/sealant. Outstanding thermal cycling capabilities and structural properties. Offers superior toughness and flexibility. Excellent strength retention at elevated temperatures. Thermally conductive/electrically insulative. Provides uniform bond line thickness. Serviceable from -100°F to +500°F. Preforms are available. |

|

EP34CA Resists -80°F to +500°F. Two component epoxy system. Long open time. Good flow properties. Can cure in section exceeding 1/4 inch thick. Withstands 1,000 hours 85°C/85% RH. Protects against aggressive chemical exposure. |

|

EP46CA-1 Serviceable from -100°F to +600°F. Tg>240°C. Oven curing. Used for structural bonding. High bond strength to similar/dissimilar surfaces. Withstands thermal cycling and chemical exposure. Electrical insulator. Long working life. |