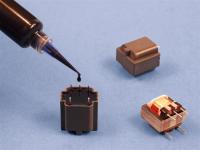

Inhibiting heat transfer is of crucial importance in many inudustrial bonding and coating applications. Many epoxy and polyurethane systems feature a range of heat insulative properties. These compounds can be used where electrical insulation or isolation is required. They offer high bond strength, low outgassing, thermal stability, excellent corrosion resistance, durability and dimensional stability. Additionally they contain no solvents and are easy to apply in thin layers.

Common Applications Featuring Thermally Insulating Compounds

Thermally insulating bonding and coating compounds help in lowering heat transfer and improving product reliability in many applications ranging from electronics devices to ovens to processing equipment to pipes to appliances.

Most Popular Thermally Insulative Compounds

|

EP30 Low viscosity two part high performance epoxy resin system. High strength rigid bonds. Low linear shrinkage after cure. Superb optical clarity and light transmission properties. Serviceable from -60°F to +250°F. Cures readily at room temperature. Withstands 1,000 hours 85°C/85% RH. |

|

EP21LV Epoxy adhesive, sealant, coating resists acids, alkalis and many solvents. Low viscosity room temperature curing. Contains no solvents. Serviceable from -60°F to +300°F. Castable to thicknesses exceeding 2-3 inches. Excellent electrical insulator. |

|

EP30D-7 Urethane-modified epoxy system. Superior toughness and abrasion resistance. Cures at room temperatures. Compound flows easily and smoothly. Versatile cure schedule. |

|

EP30HT High temperature resistant, room temperature curing epoxy system. Exceptional bond strength and dimensional stability. Optically clear. Meets FDA Chapter 1, Section 175.105 requirements. Easy to apply. Serviceable from -60° to +400°F. Protects against exposure to water, oils, fuels, acids, bases and many solvents. Rigid system. Impressive electrical insulation values. |

|

EP3HT Fast, one component heat curable adhesive. Serviceable from -60°F to +400°F. High shear strength properties. Shore D hardnes >70. "Unlimited" working life at room temperature. Superb electrical insulator. Withstands 1,000 hours 85°C/85% RH. |

|

EP42HT-2 Bonding, sealing, coating, potting compound. Heat, chemical, steam resistant. Superior optical transmission properties. Solvent free. Withstands exposure to acids, alkalis and many solvents. Castable up to 2-3 inches. Cures readily at ambient temperature. Service temperature range -60°F to +450°F. |

|

EP21TDC-2ND Two part highly flexible epoxy resin system. Smooth paste viscosity. Fills gaps. Excellent peel strength. Dependable resistance to thermal cycling. |