Conformal coatings are essential for enhancing the reliability and long-term performance of electronic assemblies. They provide superior protection against:

- Dust

- Dirt

- Abrasion

- Fungus

- Moisture

- Chemicals

- Mechanical stress

- Shock and vibration

Properties of Conformal Coatings

Master Bond conformal coatings include very fast, one part UV curing formulations, one and two part epoxies, one and two part silicones and a unique cost effective latex system. Specific grades offer:

- Low viscosity

- Wide temperature resistance

- Repairability

- Rapid cures

- High dielectric strength

- Low stress

For intricate parts with shadowed out areas we also offer special “dual cure” coatings, which cure with both UV light and the addition of heat. Other special compounds are:

- Optically clear

- Non-yellowing

- Cryogenically serviceable

- Ultra low in viscosity

Environmentally friendly, Master Bond conformal coatings are 100% reactive and contain no solvents or diluents. They can be easily dispensed without surface defects such as air bubbles/voids. Rigid/flexible coatings have good wetting characteristics, excellent strength, compatibility with a wide range of different materials/components, low outgassing, low shrinkage and are engineered to provide coverage over sharp edges/contours. These light weight products eliminate the need for enclosures and prevent high voltage arcing, corona shorts, static discharge, dendrite growth while satisfying stress relief considerations. They have proven effective in marine, space, automotive under the hood environments and other demanding conditions.

Most Popular Conformal Coating Compounds

|

EP37-3 Resilient, optically clear, two component epoxy resin system. Long working life. Excellent electrical insulation properties. Cures accelerated by heat. Chemically resistant. Low mixed viscosity. Serviceable from -80°F to +250°F. Two to one mix ratio by weight. Withstands impact. |

|

EP41S-1 Easily processable, two part epoxy with excellent chemical resistance, particularly to solvents. Available in black. 100% reactive. Low viscosity. Ambient temperature cure. Service temperature range from -60°F to +300°F. |

|

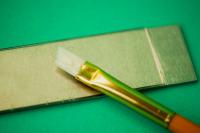

MasterSil 773 Ultra low viscosity silicone conformal coating material. Easily applied by spraying, brushing, dipping or flow coating. Superb humidity and heat resistance. |

|

EP42HT-2Med Low viscosity, two part epoxy with outstanding chemical resistance. Passes USP Class VI biocompatibility tests. Capable of withstanding repeated sterilization cycles including radiation, EtO, chemical sterilants, autoclaving. Serviceable from -60°F to +450°F. Cures at room or elevated temperatures. Available in amber-clear and black colors. Castable in thicknesses up to 2-3 inches. |

|

EP30DP-NV Two part, room temperature curing, lower viscosity system used primarily for potting and encapsulation applications. Excellent thermal cycling properties along with shock and vibration resistance. Low exotherm and long working life. Superb abrasion resistance and electrical insulation characteristics. Repairable. Serviceable from 4K to +250°F. |

|

UV15 Low viscosity, rigid UV curable system with superb thermal stability. Also capable of spin coating. Outstanding optical clarity. High bond strength. Serviceable from -80°F to +350°F. |

|

UV16 Superior chemical resistance and physical strength properties. Low shrinkage after cure. Passes NASA low outgassing tests. Excellent thermal stability. Cationic curing system. Outstanding optical clarity. Easy to apply. Low viscosity. Serviceable from -80°F to +400°F. |

|

UV22DC80-1 Dual cure system with UV and heat curing mechanisms. Cures at 80°C in shadowed out areas. Nano filled, high dimensional stability and abrasion resistance. Bonds well to metals, glass, ceramics and most plastics. Serviceable from -60°F to +350°F. |