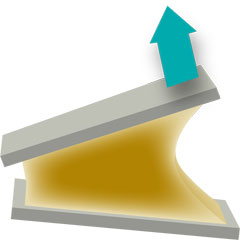

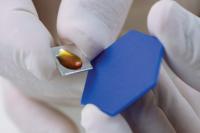

Designing the strongest possible bonded joints is an important but difficult task for engineers. Joining substrates in complex assemblies can be challenging. Engineers are faced with numerous concerns including appearance, reduced corrosion, vibration, sound dampening, lightweighting, adhering dissimilar substrates, electrical insulation, heat dissipation and other factors. Additionally a special emphasis must be placed on assembly costs.

Master Bond has developed adhesive formulations that can withstand severe stress between rigid surfaces that are opened at one end. These one and two component systems are noted for their durability, strength, electrical and thermal properties. They also possess formidable resistance to both hostile chemical vapor and immersion exposure.

Master Bond has developed adhesive formulations that can withstand severe stress between rigid surfaces that are opened at one end. These one and two component systems are noted for their durability, strength, electrical and thermal properties. They also possess formidable resistance to both hostile chemical vapor and immersion exposure.

Surface preparation is recommended to maximize performance. Our products are available for use in high and low volume applications. They are easily dispensed with manual, semiautomatic and automatic application equipment.

Most Popular High Cleavage Strength Adhesives

|

EP51FL-1 Flexible epoxy adhesive has rapid set up time and cure speed. High peel strength and elongation. Withstands mechanical shock and vibration. Resists thermal cycling. Superb electrical insulation properties. Service operating temperature range from -100°F to +250°F. |

|

Supreme 10AOHT-LO Thermally conductive and electrically insulative, one part epoxy adhesive. Superior toughness and dimensional stability. Bonds are resistant to thermal cycling and many chemicals. Serviceable from 4K to +400°F. NASA low outgassing approved. Withstands 1,000 hours 85°C/85% RH. Impressive physical strength properties. |

|

Supreme 11HT-LO Room temperature curing epoxy adhesive has a convenient one to one mix ratio. High shear and peel strength. Toughened. NASA low outgassing approved. Stress cracking fatigue resistant. Serviceable from -100°F to +400°F. Withstands 1,000 hours 85°C/85% RH. Fast setting. Good flow. Easy to apply. |

|

Supreme 42HT-2 High temperature resistant epoxy adhesive. Toughened. Excellent bond strength. Withstands exposure to many acids, bases, solvents, fuels and oils. Easy application. Service temperature range -80°F to +450°F. Good flow properties. Low exotherm. Long working life. Reliable electrical insulator. Resists thermal cycling. |