Master Bond formulates a wide range of room temperature, heat and UV curable systems that offer flowability for convenient easy application. They are recommended for adhering surfaces with tight clearances and have high bond strength to a wide range of substrates.

Applications of Master Bond’s Low Viscosity Systems

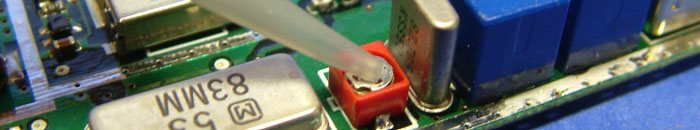

Master Bond’s low viscosity compounds are used for bonding, sealing, potting, encapsulation and impregnation applications. Their low viscosity nature facilitates filling cavities and crevices in confined areas in various cross section thicknesses. Extra low viscosity impregnants eliminate porosity in porous castings and seal against most fluids and gases.

Types of Low Viscosity One and Two Component Systems

- Epoxies

- Silicones

- Polyurethanes

- Cyanoacrylates

- Elastomeric contact cements

- UV cures

Properties of Master Bond’s Low Viscosity Compounds

Master Bond will custom formulate a product with properties that meet specific design requirements. Certain grades offer:

- High and low temperature resistance

- Fast cures

- Optical clarity

- Flexibility and toughness

- High strength

- Superior chemical resistance

Master Bond’s Most Popular Low Viscosity Adhesives, Sealants, Coatings, Potting/Encapsulation Compounds and Impregnation Resins

|

EP21LVMed Biocompatible two component epoxy adhesive, sealant, coating, encapsulant. Passes USP Class VI testing. Thermal cycling resistant. Can withstand exposure to EtO, radiation, chemical sterilants. Low viscosity. Easy to apply. Serviceable from -65°F to +250°F. |

|

MasterSil 713 Easy to use, low viscosity, one part silicone compound. Superb elasticity. Non- corrosive. Ideal for small encapsulations and conformal coatings. Clear color. Fast tack-free time. Repairable. |

|

EP30M4LV Low viscosity epoxy compound for high performance bonding, sealing, casting and potting. Impressive chemical resistance to acids, bases, fuels oils, solvents and water. Low exotherm. Serviceable from -80°F to +250°F. Superior dielectric strength. Shore D hardness 75-85. Excellent adhesion to similar and dissimilar substrates. |

|

EP30Med Biocompatible two component epoxy. USP Class VI approved. Low viscosity. Versatile cure schedules. Resists EtO, gamma radiation and cold sterilants. High strength rigid bonds. Serviceable from -60°F to +250°F. Can be used for indirect food contact per 175.105 FDA specification. |

|

EP30-3LO Superb optical clarity. Serviceable from -80°F to +450°F. T >175°C. Low viscosity and long working life. Superior dielectric properties. NASA low outgassing approved. Withstands 1,000 hours 85°C/85% RH. |

|

UV19 Single component, optically clear UV curable compound. Particularly suited for laminating, bonding substrates with different thermal expansion coefficients, such as flexible soft plastic films to polyester films, metal foils. Elongatio >80%. High impact strength. Long term chemical resistance. Serviceable from -60°F to 250°F. |

|

EP21TPFL-1 Low viscosity two component epoxy polysulfide system. Excellent resistance to water, gasoline, fuels, oils, hydrocarbons and hydraulic fluids. Outstanding flexibility. Formulated to cure at ambient temperatures. Serviceable from -60°F to +250°F. |

|

UV15DC80-10FHC UV and heat curable epoxy formulation. Cures in "shadowed out" areas at temperatures as low as 80°C. Convenient no mix system. Serviceable from -60°F to +350°F. Superb electrical insulator. Low to moderate viscosity system. |