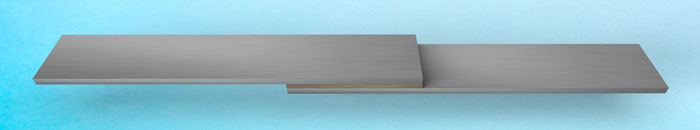

Master Bond one and two component structural adhesives offer remarkable bond strength to similar and dissimilar substrates. These compounds produce assemblies mechanically equivalent or stronger than conventional metal fastened parts at lower cost and weight. They also feature protection against corrosion and high/low temperature exposure.

Key Advantages of Master Bond Structural Adhesives

- Even distribution of stress over the entire bonded surface

- Improved load bearing capacity

- Insulator against galvanic corrosion in metal assemblies

- Enhanced structural appearance—protrusions and punctures eliminated

- Protective sealing against contamination by liquids and gases

- Weight reduction

- Resistance to cyclic fatigue

- High peel and shear strength properties

- Solvent free

- Lower cost and increased productivity

- High glass transition temperatures (Tg)

- Superior moisture and chemical resistance

- Gap filling

- Superior durability and toughness

Careful planning is the key to successful bonding. An engineer must consider several factors to maximize the performance of structural polymers including:

- Style of joint to be bonded

- Surface preparation

- Chemistry options

- Service capabilities of adhesive

- Curing requirements

Some of Our Most Popular Structural Adhesive Systems

|

Supreme 10HT One part structural epoxy with high bond strength and excellent adhesion to similar and dissimilar substrates, especially composite materials. Requires oven curing at 250-300°F. NASA low outgassing approved. Serviceable from 4k to +400°F. Tough and durable. 85°C/85% RH resistance. |

|

Supreme 42HT-2 High temperature resistant epoxy adhesive. Toughened. Excellent bond strength. Withstands exposure to many acids, bases, solvents, fuels and oils. Easy application. Service temperature range -80°F to +450°F. Good flow properties. Low exotherm. Long working life. Reliable electrical insulator. Resists thermal cycling. |

|

Rapid, room temperature curing, toughened epoxy adhesive. 100% reactive system. High peel and shear strength properites. Superior thermal cycling capabilities. Thixotropic paste. Gap filling. Chemically resistant. Non-critical one to one mix ratio by weight or volume. Resistant to vibration and shock.Serviceable from -410°F to +250°F. |

|

Supreme 11AOHT-LO Passes NASA low outgassing tests. Thixotropic paste viscosity. Convenient one to one mix ratio by weight or volume. High thermal conductivity. Excellent electrical insulation properties. Dimensionally stable. Withstands 1,000 hours 85°C/85% RH. Toughened system. Ability to resist rigorous thermal cycling. Service temperature range -112°F to +400°F. |

|

EP21TDC-2LO Highly flexibilized, thermally conductive/electrically insulative epoxy adhesive. High elongation. Exhibits superior shear and peel strength properties. Serviceable from 4K to 250°F. Withstands thermal cycling, thermal shock and mechanical shock. Passes NASA low outgassing test. Cures at room temperature or more quickly at elevated temperatures. |