Our Line of UV + Heat Dual Curing Products

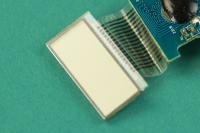

Master Bond offers a full line of 100% reactive, UV + Heat dual curing products that reach full cure with UV energy, heat energy, or both. The UV cure reduces fixturing time while heat ensures complete cure throughout the bond line, especially for areas not accessible to UV light. The thermal cure is typically initiated at temperatures as low as 80°C (176°F) which opens new opportunities for thermally sensitive substrates. These features make them ideal for applications including but not limited to electronic assemblies, and 3D printing.

Easy Curing Process of Master Bond’s Dual Curing Adhesives

These products are available in a wide range of viscosities, and they exhibit high bond strength with glass, metals, ceramics, and many plastics. They offer easy application and incredibly fast cures. The exposed areas of dual curing adhesives can cure in a few seconds when UV light is applied and the shadowed out areas cure in about 20 to 30 minutes upon exposure to heat.

Master Bond Cationic and Free Radical Dual Cure Systems

Master Bond’s extensive line of dual cure systems includes products with many different chemistries, including:

- Epoxies

- Epoxy acrylates

- Urethane acrylates

- Thiols

| Product | Key Features |

| Dual Curing products that not only meet USP Class VI for biocompatibility but also pass the ISO10993-5 test requirements for cytotoxicity | |

|---|---|

| UV15DC80Med | Designed to resist repeated autoclaving and sterilization |

| UV22DC80-1Med | Excellent optical clarity and low viscosity |

| Nano-silica filled, dual curing products not only meet NASA low outgassing requirements, but also provide excellent dimensional stability and lower shrinkage relative to other UV/Dual curing chemistries | |

| UV22DC80ND | Non-drip consistency |

| UV22DC80-10F | Moderate viscosity product |

Most Popular Dual Curing Adhesives, Sealants and Coatings

|

UV15DC80 UV and heat curable epoxy formulation. Cures in "shadowed out" areas at temperatures as low as 80°C. Convenient no mix system. Serviceable from -80°F to +350°F. Superb electrical insulator. |

|

UV22DC80-1 Dual cure system with UV and heat curing mechanisms. Cures at 80°C in shadowed out areas. Nano filled, high dimensional stability and abrasion resistance. Bonds well to metals, glass, ceramics and most plastics. Serviceable from -60°F to +350°F. |

|

UV22DC80-10F Dual cure system with UV and heat curing mechanisms. Fast cures at 80°C in shadowed out areas. Nano filled, high dimensional stability and abrasion resistance. Bonds well to metals, glass, ceramics and most plastics. Minimal shrinkage upon curing. Serviceable from -60°F to +350°F. |

|

UV22DC80ND Dual cure system with UV and heat curing mechanisms. Fast cures at 80°C in shadowed out areas. Nano filled, high dimensional stability and abrasion resistance. Bonds well to metals, glass, ceramics and most plastics. Minimal shrinkage upon curing. Serviceable from -60°F to +350°F. |

|

UV15DC80LV-FHC UV and/or heat curable modified epoxy resin system. One component 100% reactive adhesive, sealant, coating. Thermal cure at 80°C for 40-60 minutes. High bond strength. Resists moisture and chemical exposure. Serviceable up to 350°F. |