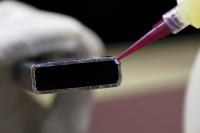

Master Bond’s non-drip formulations feature superior gap filling capabilities while maintaining outstanding bond strength to a variety of substrates. These high viscosity epoxy, polyurethane, silicone, polysulfide and UV curing systems can be applied on vertical surfaces without any sagging.

Common Applications using Non-Drip Adhesive Systems

Master Bond’s non-drip adhesive compounds are employed in a wide range of applications including:

- Filling of large gaps in worn metal surfaces

- Gap sealing in oil, gas, pressure and water tanks

- Bonding of magnet assemblies

- Protective coating for vertically oriented surfaces

Our Most Popular Non-Drip Adhesives, Sealants and Coatings

|

EP21ND Two part, room temperature curing epoxy with easy handling and very good physical strength properties. Non-drip paste. For bonding, sealing, coating. One to one mix ratio. Chemically resistant. Gap filling. Variable mix ratio allows adjusting hardness of cure. Low shrinkage. Service temperature range from -60°F to 250°F. |

|

Supreme 10HTND-3 Toughened, non-drip epoxy adhesive featuring high peel and shear strength properties. 100% reactive. Serviceable from 4k to +400°F. No viscosity change over time. Heat curable. |

|

EP21Q Two component quartz filled epoxy compound. Protects against corrosion. Paste viscosity. Paste viscosity. Can be applied on vertical surfaces without dripping. High strength system. Excellent dimensional stability. Service temperature range from -60°F to 250°F. |

|

EP40ND Excellent adhesion to metals and engineering plastics such as polycarbonates, acrylics. Flexible. For bonding, potting, sealing compound. High shear/peel strength. Resists mechanical shocks and vibration. Moderately low exotherm during cure. Serviceable from -100°F to +250°F. Paste consistency. |

|

EP21ARHTND Non-drip paste. Exceptional chemical resistance to acids. High bond strength. 100 to 50 mix ratio by weight. Formulated to cure at ambient temperatures. Used for coating pumps, storage vessels, tanks. Serviceable from -60°F to +400°F. |

|

EP22ND High performance aluminum filled epoxy with one to one mix ratio. Excellent bond strength to metal surfaces. Resists many chemicals and thermal cycling. Low shrinkage upon cure. Easy to apply. Flowable paste viscosity. Exceptionally high compressive strength. Superior dimensional stability. Easily machinable. Service operating temperature range from -60°F to +250°F. |

|

EP62-1ND Cures rapidly at elevated temperatures. Superior resistance to moisture. Two part epoxy has long pot life at ambient temperatures. High bond strength properties. Reliable electrical insulator. Serviceable from -60°F to +450°F. Shore D hardness 75-85. Thixotropic paste. |

|

Supreme 34AO Room temperature curing epoxy with high thermal stability. Serviceable from -60°F to +450°F. Thermal conductive/electrically insulative. Paste viscosity. Gap filling. Superior durability. Low CTE. High bond strength. Resists repeated thermal cycling. |