Biocompatible UV10Med is a single component, low viscosity, fast curing adhesive/sealant/coating formulated for the assembly of medical devices. It is designed to join properly prepared metal, glass, ceramic, most plastic surfaces including acrylics and polycarbonates at ambient temperatures upon UV light exposure. This product has a hardness exceeding 65 Shore D and excellent light transmission characteristics. UV10Med has superior electrical insulation properties, dimensional stability and low shrinkage upon cure.

Master Bond’s research and development team continually works to formulate new products or create enhanced versions of existing systems. These efforts led to the development of a higher viscosity, top performing UV curable compound called UV10TKMed. This product passes USP Class VI testing and meets ISO 100993-5 cytotoxicity requirements. It offers exceptional sterilization resistance. Though both products can withstand repeated cycles of radiation, ethylene oxide and chemical sterilants, UV10TKMed resists multiple cycles of autoclaving. Additionally, UV10TKMed has impressive thermal stability, reflected in its temperature resistance up to +450°F [+232°C] and a glass transition temperature of over 140°C.

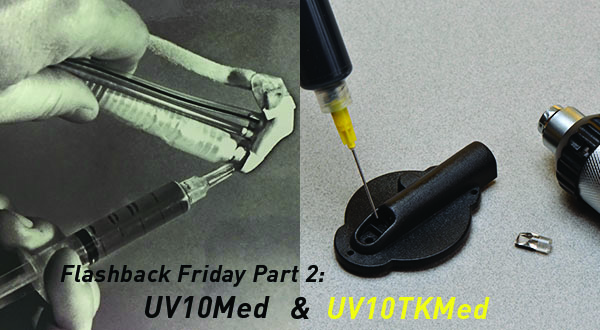

Both UV10Med and UV10TKMed can be conveniently packaged in syringe applicators. The lower viscosity UV10Med can be applied between tight clearances, while the thicker consistency UV10TKMed can cure in sections up to ¼ inch in depth. Both systems are currently being used in a wide variety of applications across the medical device industry.

For more information, request a technical data sheet on UV10Med and UV10TKMed.