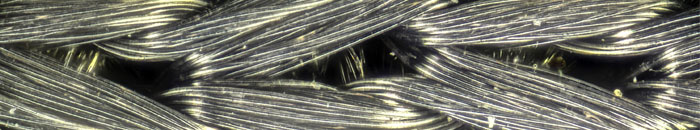

Bonding Polyamide Resins (Nylon*)

Nylon has good mechanical properties, toughness and low permeability to gases. It exhibits superior thermal stability, electrical insulation and chemical resistance. It also possesses outstanding wear/abrasion resistant characteristics.

Nylon is widely used in the following industries:

- Automotive

- Electrical

- Sports equipment

- Musical instruments

- Appliances

Some common applications include:

- Switch housing

- Car engine components

- Circuit breakers

- Fan blades

- Emission control valves

- Air condition hoses

- Fluid reservoirs

- Gears

Master Bond formulates epoxy and polyurethane adhesives to bond nylon to nylon and nylon to dissimilar substrates. These compounds offer reliable solutions for demanding requirements.

For more information on bonding plastic substrates take a look at our surface preparation guide.

Lap shear strength of adhesives for nylon: testing results for select Master Bond epoxy adhesives

Consideration for Bonding Polyamide Resins (Nylon*)

Important products for adhesive bonding of polyamide resins include EP30P, EP41SMed, EP21LV3/5Med and EP21ND. Master Bond EP30P is a high strength, two component epoxy with superb optical clarity. This low viscosity system has superior electrical insulation properties and exceptionally low shrinkage upon cure. USP Class VI approved EP41SMed and EP21LV3/5Med cure readily at ambient temperatures. EP41SMed produces rigid bonds, fast "handling" time and resistance to sterilants. EP21LV3/5Med has an elongation over 23%, flows smoothly and can withstand vibration, shock and thermal cycling. Non-drip EP21ND has a convenient one to one mix ratio. This epoxy paste offers superior dimensional stability and is serviceable from -60°F to +250°F.

*Nylon is manufactured by companies including: E.I. Du Pont (Zytel®), BASF (Ultramid®), Atochem N.A. (Rilsan®), Hoescht Celanese (Celstran®) and Toray Industries (Amilan®).